Last Updated on November 27, 2025 by Bilal Hasdemir

Robots are now doing tasks that are hard for people. They are good at tasks that are dull, dirty, dangerous, or expensive. This is known as the 4 D’s.

The 4 Ds of robots mean robots are perfect for tasks that are boring, risky, or too costly. They help make work safer and more efficient in many fields.

Knowing what the definition of 4 D’s of robots is helps us see how they are changing work. Robots are making jobs safer and cleaner by doing tasks that were once too risky or dirty.

To understand robot deployment, we must look at its history. It started because humans couldn’t do certain tasks safely or efficiently.

The history of robotics is about making work safer and more efficient. At first, robots were made to do simple, repetitive tasks well. Now, they can handle complex tasks thanks to new technology.

Robotics has grown thanks to better engineering, electronics, and computer science. These advances let robots work in many places, from factories to dangerous sites.

Sorting tasks for robots is key in robotics. It helps figure out which tasks robots can do best. Tasks are grouped into dull, dirty, dangerous, and dear (expensive) to guide robot use.

| Task Category | Description | Robot Suitability |

| Dull | Repetitive tasks | High |

| Dirty | Tasks in contaminated environments | High |

| Dangerous | Hazardous tasks | High |

| Dear (Expensive) | Cost-prohibitive human labor | High |

The 4 D’s of robots – dull, dirty, dangerous, and dear – are key in modern automation. They guide the use of robots in many industries.

The 4 D’s started in the early days of robotics. They focused on tasks humans didn’t want to do. Over time, they grew to include more tasks, based on their nature. The evolution of the 4 D’s has been key in shaping modern automation.

The 4 D’s came from the need to sort tasks in robotics. As robots entered different areas, it was clear some tasks were better for them. The 4 D’s helped sort these tasks well.

The 4 D’s define modern automation by giving a clear way to decide who does what. By identifying tasks that fit these categories, businesses can see where robots can help most.

These categories are important because they show how robots can handle tasks that are too boring or risky for humans. This makes work safer and more productive.

The 4 D’s framework helps decide when to use robots. It categorizes tasks based on their nature. By understanding the tasks, companies can choose the right robots for the job.

For example, tasks that are dull or dirty can be done by robots. This frees up people for more complex and creative tasks.

Businesses can greatly improve efficiency by automating dull tasks. These tasks are often boring and take up a lot of time. Robots and automated systems are now used to do these jobs, letting humans focus on more interesting and creative tasks.

Dull tasks are repetitive and don’t require much thinking or decision-making. They can make workers tired and less productive over time. Examples include assembly line work, data entry, and moving materials. Automating these tasks makes work more efficient and cuts down on mistakes.

Robots are used in many industries for repetitive tasks. In manufacturing, they do jobs like welding, painting, and putting parts together. In the service sector, they help with data entry and customer service. They also excel in moving goods and products in warehouses and distribution centers.

Automating dull tasks brings big productivity gains. It makes work more interesting and helps workers stay focused. This lets humans do tasks that need creativity, problem-solving, and innovation. This leads to better productivity and efficiency overall.

Key benefits of automating dull tasks include:

By automating dull tasks, companies can enjoy these benefits. This helps them grow and stay competitive in the future.

Robots are now key in many industries, working in dirty and dangerous places. They help in places like nuclear sites, chemical plants, and areas with toxic waste. This is because they help keep humans safe and protect the environment.

In work and science, “dirty” means places with harmful stuff like toxic substances. These places are risky for people, so robots are used to keep them safe.

Key characteristics of dirty environments include:

Many industries use robots to keep things clean and safe. These include:

Using robots in these places makes work safer for humans. It also helps protect the environment.

Robots in dirty places are good for both the environment and worker health. They do jobs in polluted areas, stopping the spread of harmful stuff. This makes work safer for people and helps the planet.

The benefits include:

Robots are now used in dangerous places to keep humans safe. The term ‘dangerous’ shows how robots help with tasks that are risky for people. By doing these tasks, robots make workplaces safer and lower the chance of accidents.

Workplaces can be dangerous in different ways. Some have toxic substances, high temperatures, or explosive materials. Others are physically demanding and could cause injuries. Robots can work in these places, protecting human workers from harm.

Robots take on tasks that are too risky for humans. For example, in bomb disposal, robots help defuse bombs, keeping people safe. In factories with dangerous materials, robots handle these, protecting workers.

Using robots in these situations saves lives and keeps operations running smoothly. This is key in industries where stopping work can cost a lot of money.

Many stories show how robots save lives. In disaster rescue efforts, robots help find survivors and check damage safely. This way, rescue teams stay safe.

| Industry | Robot Deployment | Outcome |

| Bomb Disposal | Robots used to defuse explosives | Lives saved, risk minimized |

| Search and Rescue | Robots deployed for survivor location | Survivors found, rescue teams kept safe |

| Hazardous Manufacturing | Robots handling hazardous materials | Reduced exposure to human workers |

These examples show how important robots are in making dangerous tasks safer. They save lives and make workplaces safer for everyone.

The fourth D, “dear,” stands for tasks that cost a lot when done by humans. Using robots for these tasks can save a lot of money and make things more efficient.

Cost-prohibitive human labor means tasks that cost too much when done by people. These tasks often need special skills, are dangerous, or need to run all the time. Finding these tasks helps businesses know where to use automation best.

Examples of such labor include:

Using robots for expensive tasks has many long-term financial perks. Robots don’t need wages, benefits, or training. They also work all the time, boosting productivity and cutting down on overtime.

The benefits are:

ROI analysisis key to seeing if automation is worth it. It compares the money saved and work done to the cost of robots and upkeep.

Businesses use ROI analysis to check if automation is good for their wallet. This includes looking at the cost of starting up, running costs, and how much money or work they’ll save.

By using ROI analysis, companies can decide smartly where to use automation. This ensures their money is well spent.

The 4 D’s of robots are changing manufacturing. They make it more efficient, safer, and improve product quality. By handling dull, dirty, dangerous, and dear tasks, manufacturers see big improvements.

Robots take over repetitive tasks, letting humans do more complex work. This makes production lines better, cutting down on delays and boosting efficiency.

Robots also boost quality control and consistency. They work with high precision, cutting down on mistakes. This means better products and less waste.

| Aspect | Human Labor | Robotics |

| Precision | Variable | High |

| Consistency | Prone to fatigue | Consistent |

| Error Rate | Higher | Lower |

The arrival of robots in manufacturing means workers need new skills. They must learn about robotics maintenance, programming, and operation.

By understanding these changes, manufacturers can help their workforce adapt. This ensures a smooth transition and makes the most of robotic technology.

The 4 D’s concept greatly influences robot design and engineering. It helps create robots for dull, dirty, dangerous, and dear tasks.

Engineers must think about each D category’s needs. For example, robots for dirty places need to be sealed. Those for dangerous tasks must be strong.

Different D categories need different hardware. For example:

The debate on specialized vs. multi-purpose robots is ongoing. Specialized robots excel in one task but are limited. Multi-purpose robots are flexible but not as good in one task.

The choice depends on the task, environment, and cost. It’s about finding the right balance.

Key factors include:

By considering these, engineers can design robots that fit the 4 D’s concept. This meets the needs of many industries and applications.

Robot programming is key in the 4 D’s framework. It helps develop software for tasks and adapting to new situations. This is important for robots in many fields.

The 4 D’s – Dull, Dirty, Dangerous, and Dear (or Expensive) – help sort tasks for robots. Robot programming is essential for these tasks.

Task categorization is vital in robot programming. It uses software to sort tasks based on their nature. This includes tasks that are repetitive, dangerous, or costly.

For example, a task might be “Dull” if it’s repetitive. Software like ROS helps create these sorting algorithms.

Adaptive algorithms are key for robots to adjust to new situations. They let robots learn and change their actions based on their environment.

| Algorithm Type | Functionality | Benefit |

| Machine Learning | Enables robots to learn from data | Improves task efficiency |

| Sensor Integration | Allows robots to perceive their environment | Enhances adaptability |

| Real-time Processing | Facilitates immediate response to changes | Reduces downtime |

Adaptive algorithms make sure robots work well in changing environments.

A robotics expert said,

“The ability of robots to adapt to new situations is what will drive the future of automation.”

Starting the 4 D’s of automation comes with many hurdles. These issues touch on technical, economic, and operational areas. A broad strategy is needed to tackle these problems.

One big challenge is the technical hurdle to full use. It’s hard to fit robots into current work flows. Also, making sure they work with different systems and creating smart AI is tough. Technical limitations make it hard to fully adopt the 4 D’s, needing a lot of research and development.

The cost of starting automation is a big factor. The first investment can be high, and companies must think about the long-term benefits. A careful look at costs and benefits is key to deciding if automation is right.

| Cost Factor | Initial Investment | Long-term Savings |

| Hardware and Software | $100,000 | $50,000/year |

| Training and Maintenance | $20,000 | $10,000/year |

Adding robots to human work flows is another big challenge. It’s important to plan well so robots help, not hinder, human workers. This means changing work flows, training staff, and setting up good ways for humans and robots to work together.

Robot deployment in the 4 D’s categories needs specific safety rules and laws. It’s key to keep everyone safe as robots join more industries, like making things and healthcare.

Safety standards are very important. They help make sure robots work well with people. This is to avoid accidents and make sure everyone works together smoothly.

Human-robot collaboration (HRC) is getting more common. It needs safety rules to keep workers safe and make robots work better. Important parts include:

To use these rules well, you need to know a lot about the robots and the place they work in.

Each industry has its own rules for using robots. For example, making things and healthcare have their own rules because of their different work.

| Industry | Regulatory Focus | Key Safety Standards |

| Manufacturing | Production line safety, machinery operation | OSHA guidelines, ISO 10218 |

| Healthcare | Patient and staff safety, infection control | HIPAA compliance, FDA regulations |

Knowing and following these specific rules is very important for robots to be used safely in the 4 D’s.

The 4 D’s of robots offer a detailed way to check and boost robot performance. To get the most from robots, it’s key to measure and improve their performance using the 4 D’s.

To really measure robot performance, setting key performance indicators (KPIs) for each 4 D’s category is essential. For “Dull” tasks, KPIs might include how often tasks are done and how fast. For “Dirty” environments, focus on keeping things clean and safe.

| D Category | Key Performance Indicators |

| Dull | Task completion rate, cycle time |

| Dirty | Contamination control, environmental safety |

| Dangerous | Accident rate, worker safety |

| Dear (Expensive) | Cost savings, return on investment (ROI) |

Keeping things better is key for robot performance. Using Lean manufacturing and Total Productive Maintenance (TPM) helps find and fix problems. Looking at KPI data often makes robot work better and more efficient.

By using the 4 D’s, strong KPIs, and ongoing improvement, companies can really boost their robot performance. This leads to better and more efficient work.

The future of robotics is exciting, with new dimensions beyond the 4 D’s framework. Robotics and AI are advancing fast. This will change industries and how tasks are automated.

A new fifth D might be decision-making autonomy. Robots and AI are getting smarter. They can now make decisions on their own.

This change will make industries better by speeding up responses and improving processes.

Key aspects of decision-making autonomy include:

Predictive analysis and proactive task management are key for robotics’ future. Robots can now plan ahead with predictive analytics. This cuts downtime and boosts efficiency.

Benefits of predictive analysis include:

As we look ahead, combining these advancements is vital. It will shape robotics and AI’s future. By embracing these changes, industries can lead and benefit from automation.

The 4 D’s of robots have changed the game in many industries. They help with tasks that are dull, dirty, dangerous, or expensive. This approach has made processes more efficient, safer, and better in many areas.

In manufacturing, robots take over repetitive tasks like assembly and welding. A big car maker used robots for welding and saw a 25% increase in production efficiency. Robots also make products better by cutting down on human mistakes.

| Industry | Task | Robot Type | Efficiency Gain |

| Automotive | Welding | Robotic Arm | 25% |

| Electronics | Assembly | SCARA Robot | 30% |

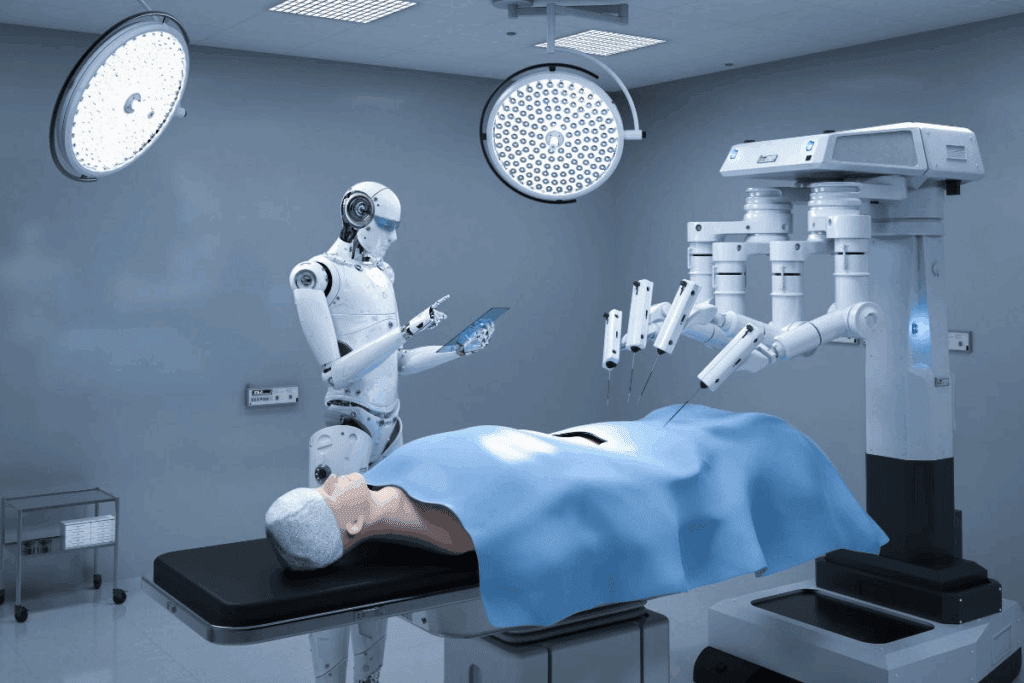

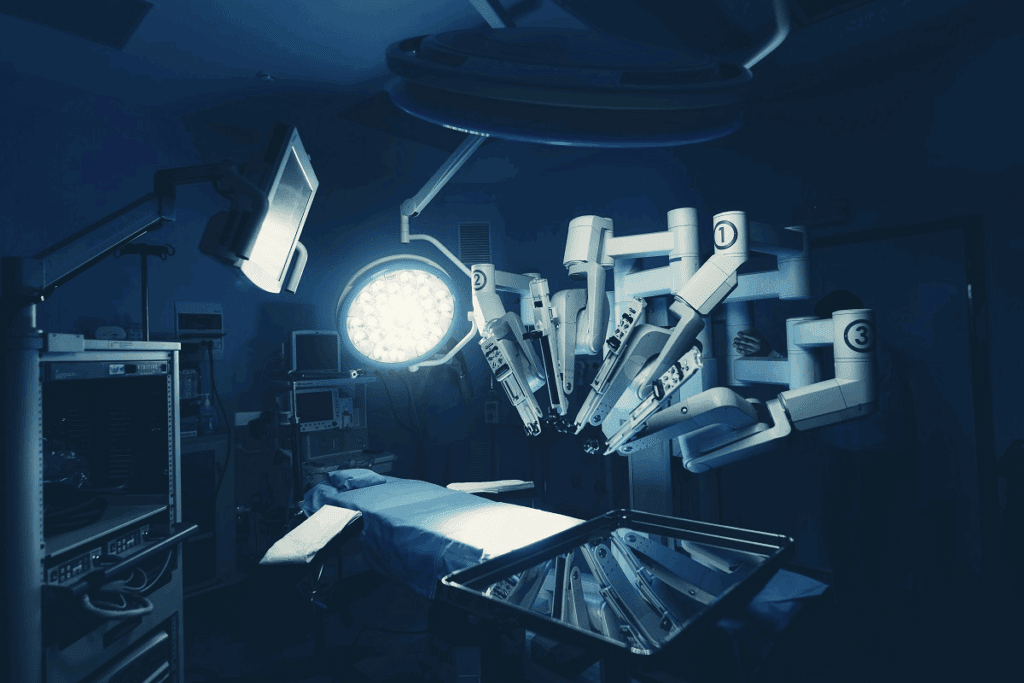

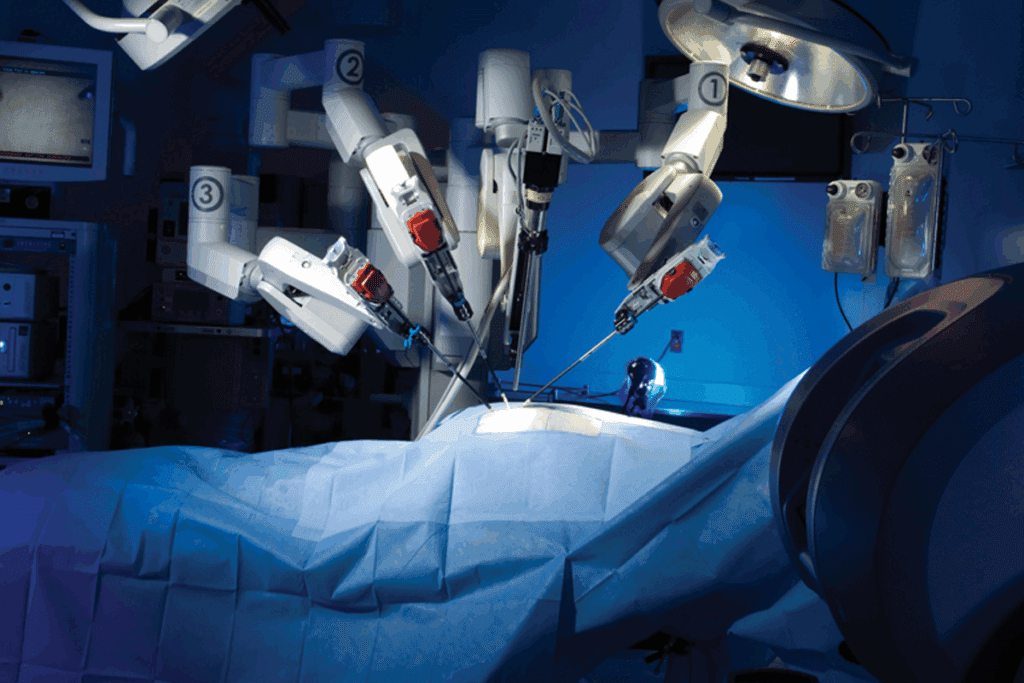

Robots are making healthcare safer and more efficient. They handle dangerous tasks like working with hazardous materials or helping in surgeries. For example, they help in minimally invasive surgeries, making operations more precise and reducing recovery times.

Robots also help in hospitals with tasks like cleaning and caring for patients.

In exploration and research, robots open up new areas for scientists. They can go where humans can’t, like deep underwater or to other planets. These robots have advanced sensors and systems for real-time data.

The 4 D’s of robots have changed how tasks are done in many fields. They sort tasks into Dull, Dirty, Dangerous, and Dear (Expensive). This helps businesses use robots to work better, save money, and keep workers safe.

In places like manufacturing, healthcare, and exploration, robots do tasks that are boring, risky, or dirty. This change has made things more efficient. It also lets humans do more creative and problem-solving work.

As industries grow, knowing and using the 4 D’s will be key for innovation and growth. By using robotics and automation, companies can lead the way and find new chances for growth. The 4 D’s will keep being important in shaping the future of work and society.

The 4 D’s of robots are tasks that robots can automate. These include dull, dirty, dangerous, and dear (expensive) tasks. They help us know which tasks are best for robots.

The 4 D’s framework started as a way to sort tasks for robots. It has grown to be a key idea in robotics and automation.

The 4 D’s help decide when to use robots. They look at tasks that are dull, dirty, dangerous, or expensive. This helps companies choose the right projects and use resources well.

Robots do tasks like repetitive assembly, material handling, and inspections. They do these tasks well because they are accurate and efficient.

Robots take over tasks in dirty places, keeping workers safe. This reduces injuries and illnesses, making workplaces safer.

Robots are used in risky jobs like search and rescue, nuclear work, and handling hazardous materials. They show how robots can make work safer.

The 4 D’s help make manufacturing better by automating tasks. This boosts productivity, quality, and efficiency. It helps companies stay ahead in a fast-changing market.

Implementing the 4 D’s can face technical, economic, and integration challenges. Companies must think about these when planning to use robots.

Robot performance can be tracked and improved with the 4 D’s. By using key performance indicators and continuous improvement, companies can get the most from their robots.

The 4 D’s might soon include a fifth D for decision-making autonomy. This will let robots make more complex decisions, improving productivity and efficiency even more.

Forbes —The 4 Ds Of Robotization: Dull, Dirty, Dangerous And Dear

Subscribe to our e-newsletter to stay informed about the latest innovations in the world of health and exclusive offers!