Last Updated on November 27, 2025 by Bilal Hasdemir

At Liv Hospital, we lead in treating mitral valve disease with mechanical MVR technology. This disease can harm heart function, making life less energetic. Mechanical MVR is a key treatment, boosting heart function and energy in patients.

The way the valve is set is key for energy recovery. We make sure the valve is set right to improve heart function. Our team focuses on patient care, using mechanical MVR to tailor treatments.

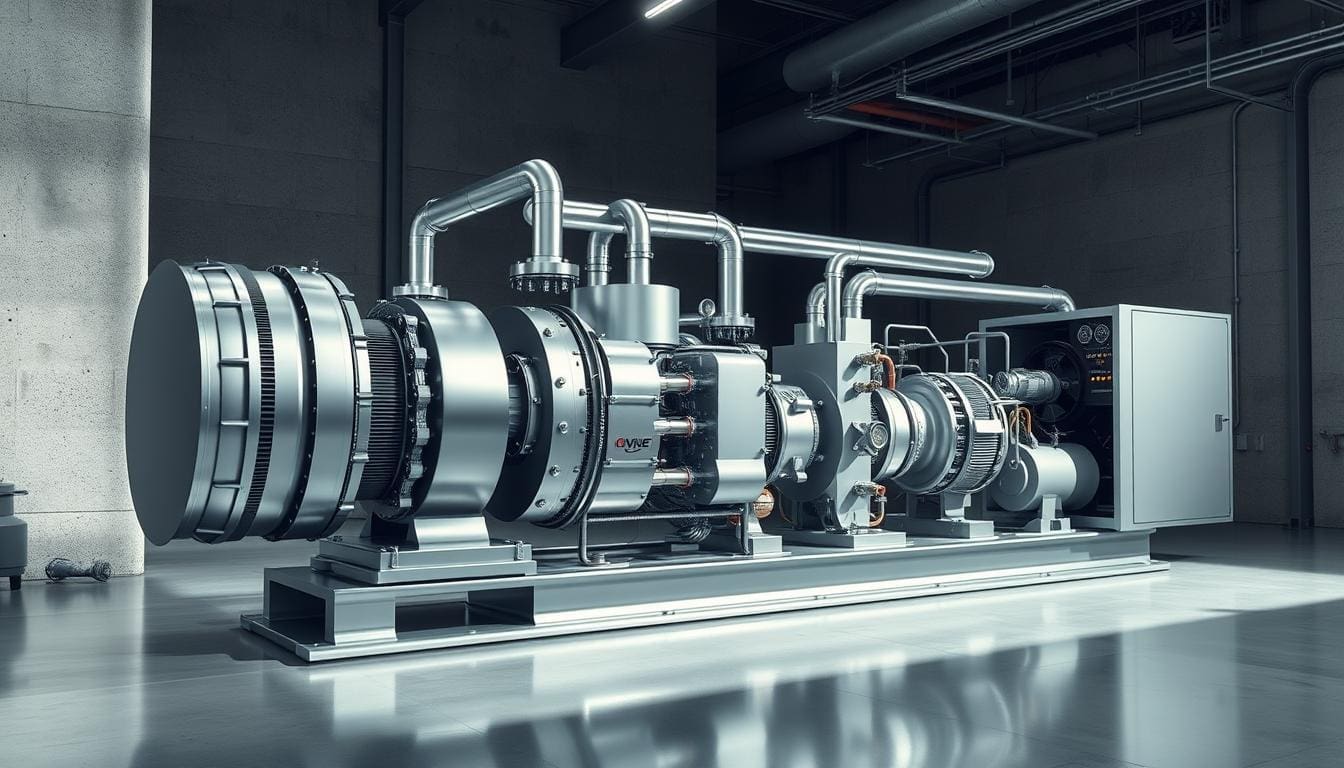

Understanding Mechanical MVR technology is key for industries looking to save energy. Mechanical Vapor Recompression (MVR) is a method that helps cut down energy use in many industrial processes.

We will look into what Mechanical MVR is, its history, and how it works. This will give us a better understanding of its growth and uses today.

Mechanical Vapor Recompression is a method that compresses vapor to make it hotter and pressurized. This allows it to be reused in industrial processes. It’s especially useful when vapor is a byproduct, like in evaporation and distillation.

By compressing vapor, industries can use less energy. This is because the compressed vapor can act as a heat source. It makes processes more energy-efficient and cuts down on carbon emissions.

The idea of Mechanical Vapor Recompression has been around for decades. At first, it was used in a few places because of tech limitations and high costs. But, with better compressors and control systems, MVR has become more practical and efficient.

Over time, the need for energy-saving industrial processes has driven MVR’s development. As energy prices go up, industries are turning to MVR to cut costs and energy use.

For example, Aemetis’ California Ethanol Plant has used MVR to greatly reduce carbon emissions.

The core of Mechanical MVR is compressing vapor to make it hotter and pressurized. This is done with a compressor, which heats the vapor. This heated vapor is then used as a heat source in various industrial processes.

The efficiency of MVR depends on several things. These include the compression ratio, temperature difference, and system size. Getting these right is key to maximizing energy recovery and efficiency.

| Component | Function | Importance |

|---|---|---|

| Compressor | Compresses vapor to increase temperature and pressure | High |

| Heat Exchanger | Transfers heat from compressed vapor to process | High |

| Control System | Monitors and controls MVR process parameters | Medium |

Mechanical MVR technology is changing the game in industry by saving a lot of energy. It does this through advanced vapor recompression. This is key to making mechanical MVR systems more efficient.

The heart of mechanical MVR’s energy-saving trick is vapor recompression. It compresses vapor, which heats it up. This heat is then used to save energy. This makes the system more efficient by needing less outside energy.

Heat recovery is a big deal in mechanical MVR systems. It captures and uses the heat from vapor recompression. This boosts the system’s energy-saving abilities. It helps cut down energy use and costs.

How well a system turns energy into something useful is key. Mechanical MVR systems do this well. They turn the energy saved into something useful. This is great for companies looking to save on energy and costs.

In short, mechanical MVR is a top-notch way to save energy. It uses vapor recompression, smart heat recovery, and efficient energy use. By getting these right, industries can get the most out of their mechanical MVR systems.

To get the most out of MVR systems, they need the right parts. This includes compressors, heat exchangers, and control systems. Choosing these components well is key to the mechanical MVR technology‘s success.

The compressor is at the heart of an MVR system. It compresses vapor to raise its temperature and help with heat transfer. There are different types of compressors, like centrifugal, Roots-type, and screw compressors. The right one depends on the mechanical MVR application and needed compression.

| Compressor Type | Advantages | Typical Applications |

|---|---|---|

| Centrifugal | High flow rates, compact design | Large-scale industrial processes |

| Roots-type | High compression ratios, reliable | Applications requiring high pressure |

| Screw | High efficiency, flexible operation | Various industrial processes, including wastewater treatment |

Heat exchangers are crucial in the mechanical MVR process. They help transfer heat from the compressed vapor to the process fluid efficiently. The design and choice of heat exchangers are vital for top performance and energy savings.

When picking heat exchangers, we must think about the heat transfer area, material, and resistance to fouling.

Advanced control systems are key for MVR systems to work their best. These systems watch and adjust things like compression ratio, flow rates, and temperatures in real-time. This ensures the system runs efficiently.

With smart control systems, we can see big boosts in energy efficiency and system reliability.

The efficiency of mechanical vapor recompression (MVR) systems depends on several key factors. Knowing these factors is key to getting the most out of MVR technology in industrial settings.

Getting the compression ratio right is crucial for MVR efficiency. The compression ratio impacts energy use and system performance. A well-optimized ratio helps the system work at its best, saving energy and boosting efficiency.

Key considerations for compression ratio optimization include:

Managing the temperature difference between vapor and condensate is vital for MVR efficiency. This difference affects heat transfer efficiency. Keeping it in check is essential for system performance and preventing problems like fouling or scaling.

Strategies for temperature differential management include:

Proper system sizing and capacity planning are crucial for efficient MVR operation. A system that’s the right size can handle the load without wasting energy.

Best practices for system sizing include:

By focusing on these efficiency factors, industries can greatly improve their mechanical MVR systems. This leads to better energy recovery, lower costs, and higher efficiency overall.

Mechnical MVR is used in many fields, like food processing and making medicines. It’s great for saving energy and cutting costs. This makes it a key part of many industries.

In the food world, mechanical MVR helps with evaporation and drying. It keeps food quality high and uses less energy. For example, it makes fruit concentrates more efficiently by using vapor energy.

Benefits in Food Processing:

Chemical making needs careful temperature control and energy use. Mechanical MVR helps make these processes better and cheaper. It’s good for things like making crystals and drying substances.

For treating wastewater, mechanical MVR concentrates waste. This means less water to treat or throw away. It also helps get valuable stuff back from waste.

The drug-making world gets a lot from mechanical MVR. It’s gentle with sensitive products. It’s used for drying and making granules, keeping quality high and energy use low.

| Industry | Application | Benefits |

|---|---|---|

| Food and Beverage | Evaporation, Concentration, Drying | Energy savings, Improved product quality |

| Chemical Manufacturing | Crystallization, Distillation, Drying | Improved efficiency, Reduced operational costs |

| Wastewater Treatment | Waste concentration | Reduced wastewater volume, Resource recovery |

| Pharmaceutical | Drying, Granulation | Gentle product handling, Energy efficiency |

Using mechanical MVR, industries can save a lot of energy and money. It shows how important it is for making things better and greener.

Using Mechanical MVR technology helps industries cut down on costs and reduce carbon footprint. This is why more sectors are turning to Mechanical MVR systems.

Mechanical MVR cuts down operational costs. It does this by reusing energy that would otherwise be lost. This lowers energy use and saves money, making operations more efficient.

Let’s look at how much money can be saved with Mechanical MVR:

| Industry | Energy Cost Without MVR | Energy Cost With MVR | Cost Savings |

|---|---|---|---|

| Food Processing | $100,000 | $70,000 | 30% |

| Chemical Manufacturing | $150,000 | $105,000 | 30% |

| Wastewater Treatment | $80,000 | $56,000 | 30% |

Understanding the return on investment (ROI) is key when adopting Mechanical MVR. The ROI is based on energy savings and the initial cost. Industries can see a big return in just a few years, making it a smart choice.

For example, if a Mechanical MVR system costs $500,000 and saves $150,000 a year, the ROI is about 3.3 years.

Mechanical MVR also has big environmental benefits. It cuts down on energy use and greenhouse gas emissions. This helps industries meet environmental rules and boosts their green image.

In summary, Mechanical MVR offers great economic and environmental advantages. It’s a key solution for industries wanting to save money and reduce their environmental impact. As we look for ways to make industries more efficient and green, Mechanical MVR will play a bigger role.

When we think about adding mechanical MVR technology to existing places, we face several important steps. We need to check if it’s possible, tackle any problems, and look at successful examples.

First, we do a detailed check to see if MVR technology fits. We look at the current setup, energy use, and how things work now. This helps us decide if MVR is right for the place.

We look at things like:

This study helps us find any big issues and chances to make things better. It makes sure the switch to MVR goes smoothly.

Adding MVR technology to old places can be tricky. Some problems might be:

To solve these problems, we use a few plans:

These plans help reduce trouble and make sure the MVR technology works well.

Many places have put in mechanical MVR technology and seen big energy savings. Here are a few examples:

| Industry | Energy Savings | Payback Period |

|---|---|---|

| Food Processing | 30% | 3.5 years |

| Chemical Manufacturing | 25% | 4.2 years |

| Pharmaceutical Production | 40% | 3.8 years |

These examples show the good things that can happen with MVR technology. By learning from them, we can do a better job and get more benefits.

To make mechanical MVR systems work better, we need regular upkeep, fine-tuning, and new tech. We’ll dive into these steps to help you keep your system running smoothly and efficiently.

Keeping your mechanical MVR system in top shape is crucial. Routine checks should cover the compressor, heat exchangers, and control systems. Look for any wear or problems.

“Regular maintenance is key to preventing system failures and maintaining optimal performance,” as emphasized by industry experts. A predictive maintenance schedule can spot issues early.

Getting your mechanical MVR system to run at its best is vital. This means optimizing the compression ratio and keeping it within its design limits.

To fine-tune your system, you need to know how it works. Advanced control algorithms can adjust the system in real-time, adapting to changes.

“Advanced control systems can significantly enhance the efficiency and reliability of mechanical MVR systems by ensuring they operate at optimal levels.”

New tech is key to boosting mechanical MVR system efficiency. Upgrading to more efficient compressors or using advanced materials for heat exchangers can make a big difference.

Keeping up with the latest tech and adding it to your system can greatly improve efficiency and productivity. Look into upgrading parts and using new tech to boost your system’s performance.

| Technological Upgrade | Potential Benefit |

|---|---|

| Advanced Compressor Designs | Increased Efficiency |

| Improved Heat Exchanger Materials | Enhanced Heat Transfer |

| Smart Control Systems | Optimized Performance |

MVR systems are very efficient but face some common challenges. To work well, we need to understand these issues and find ways to solve them.

Technical issues are a big problem in MVR systems. These include compressor inefficiencies, inadequate heat exchanger design, and control system limitations. Choosing the right compressor is key to solving these problems.

Using high-efficiency compressors and advanced materials can make MVR systems better. Keeping the compressor and other parts well-maintained is also important.

Scale and fouling can make MVR systems less efficient and cost more to maintain. Scale happens when minerals in the vapor stick to the heat exchanger. To stop this, regular cleaning and maintenance schedules are needed, along with chemical treatments to prevent scaling.

Fouling can be avoided by good system design and operation. Using the right filtration systems and keeping the system running well helps. Watching the system’s performance closely can catch problems early.

Energy changes can affect MVR system performance. These changes can come from vapor flow rate changes, operating condition changes, or external factors like power supply issues. Using advanced control systems helps manage these changes.

Adding energy storage solutions or backup power systems can also help. They keep the energy supply steady, even when there are changes.

Industries are looking for ways to be more sustainable and efficient. Mechanical MVR technology is key in this area. The Aemetis California Ethanol Plant is a great example, using Praj’s low-carbon MVR system.

This system is expected to cut natural gas use by about 80%. It will also bring in around $32 more each year. This is from saving energy and making more money.

This project shows how mechanical MVR can cut down on carbon and save money. It got about $19.7 in grants and tax credits. This shows it’s a smart financial move.

As we go forward, we’ll see more of this technology. It will make industrial mechanical MVR even more efficient.

For more details, check out the Aemetis California Ethanol Plant’s project update. It shows how mechanical MVR boosts energy efficiency in industries.

Mechanical Vapor Recompression (MVR) is a way to use energy from vapor streams. It compresses them to a higher pressure and temperature. This makes it possible to use the energy again in industrial processes. We use MVR to save energy and make processes more efficient in many industries.

Using Mechanical MVR brings big energy savings and lower costs. It also cuts down on carbon emissions. MVR boosts efficiency and reduces environmental harm in food, chemicals, and pharmaceuticals.

MVR recovers energy by compressing vapor to a higher pressure and temperature. This makes it reusable. We also use heat recovery to boost efficiency. Our systems are designed to turn energy into useful work efficiently.

An efficient MVR system needs good compressors, heat exchangers, and control systems. We pick compressors based on what’s needed. Our heat exchangers are made to transfer heat well. Our control systems keep everything running smoothly and efficiently.

Adding MVR to existing places needs a good plan. We check the setup, find problems, and solve them. Our team has made MVR work in many places, saving a lot of energy and improving efficiency.

MVR can face issues like technical limits, scale, and energy changes. We have ways to deal with these, like regular checks and new tech. Our team works hard to keep MVR systems running well.

To make MVR systems better, do regular checks and updates. Clean and inspect equipment, and use tuning to get the best results. Our team helps clients get the most out of their MVR systems.

The ROI for MVR depends on how it’s used. We do detailed calculations to show the savings and payback time. Our studies show MVR can be very profitable in many fields.

MVR helps cut down carbon emissions by using less energy. It reduces the need for outside energy. We’ve seen big cuts in greenhouse gases in many industries, helping the planet.

FAQ

Mechanical Vapor Recompression (MVR) is a way to use energy from vapor streams. It compresses them to a higher pressure and temperature. This makes it possible to use the energy again in industrial processes. We use MVR to save energy and make processes more efficient in many industries.

Using Mechanical MVR brings big energy savings and lower costs. It also cuts down on carbon emissions. MVR boosts efficiency and reduces environmental harm in food, chemicals, and pharmaceuticals.

MVR recovers energy by compressing vapor to a higher pressure and temperature. This makes it reusable. We also use heat recovery to boost efficiency. Our systems are designed to turn energy into useful work efficiently.

An efficient MVR system needs good compressors, heat exchangers, and control systems. We pick compressors based on what’s needed. Our heat exchangers are made to transfer heat well. Our control systems keep everything running smoothly and efficiently.

Adding MVR to existing places needs a good plan. We check the setup, find problems, and solve them. Our team has made MVR work in many places, saving a lot of energy and improving efficiency.

MVR can face issues like technical limits, scale, and energy changes. We have ways to deal with these, like regular checks and new tech. Our team works hard to keep MVR systems running well.

To make MVR systems better, do regular checks and updates. Clean and inspect equipment, and use tuning to get the best results. Our team helps clients get the most out of their MVR systems.

The ROI for MVR depends on how it’s used. We do detailed calculations to show the savings and payback time. Our studies show MVR can be very profitable in many fields.

MVR helps cut down carbon emissions by using less energy. It reduces the need for outside energy. We’ve seen big cuts in greenhouse gases in many industries, helping the planet.

References

Abbott — Living with Your New Heart Valve (Patient Guide)

PMC (PubMed Central) — Mechanical Valves: Past, Present, and Future — A Review

PubMed — 28389690

Medtronic — Aortic & Mitral Valve Replacement Surgery — Benefits & Risks

Healthgrades — Recovery After Mitral Valve Surgery: What to Expect

Subscribe to our e-newsletter to stay informed about the latest innovations in the world of health and exclusive offers!