At Liv Hospital, we use the latest medical technology to provide top-notch care. Infrared (IR) technology is changing how we do injections. It uses non-invasive thermal imaging and therapy. Infrared technology helps find tissue problems early, picks the best injection spots, and watches how tissues react in real-time. This makes treatments safer and more effective. Discover 5 amazing advantages of using infrared technology for an IR injection. Learn how this tech improves accuracy and safety.

Infrared lamps send out infrared radiation, which we can’t see but feel as heat. This tech is great for controlled heating or drying in certain tasks.

Key Takeaways

- Infrared technology makes injection processes more precise.

- It lets us watch how tissues react in real-time.

- IR technology makes medical procedures less uncomfortable.

- It helps healing by delivering thermal energy better.

- Liv Hospital uses IR technology for better patient care.

The Evolution of IR Technology in Medical and Industrial Applications

IR technology has grown a lot, moving from a special tool to a common use in health and industry. This change came from better infrared temperature control and more energy-efficient IR injection methods.

Historical Development of Infrared Technology

IR technology started for military and spy use. But, its special features made it very useful in health checks and industrial work. Key moments in IR technology’s history include finding infrared radiation and making thermal imaging cameras.

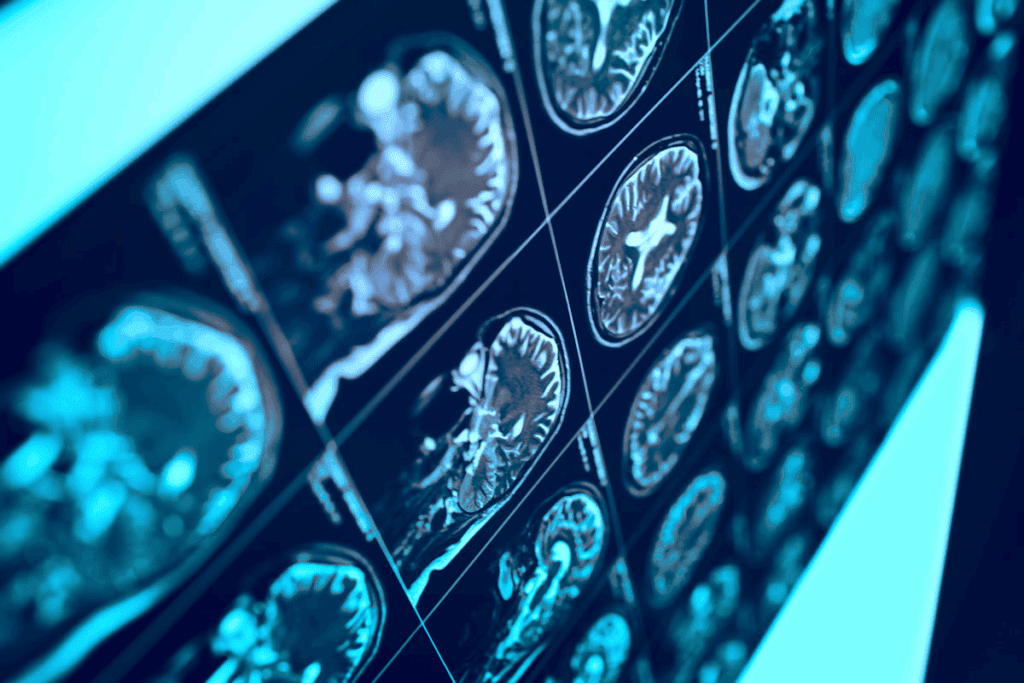

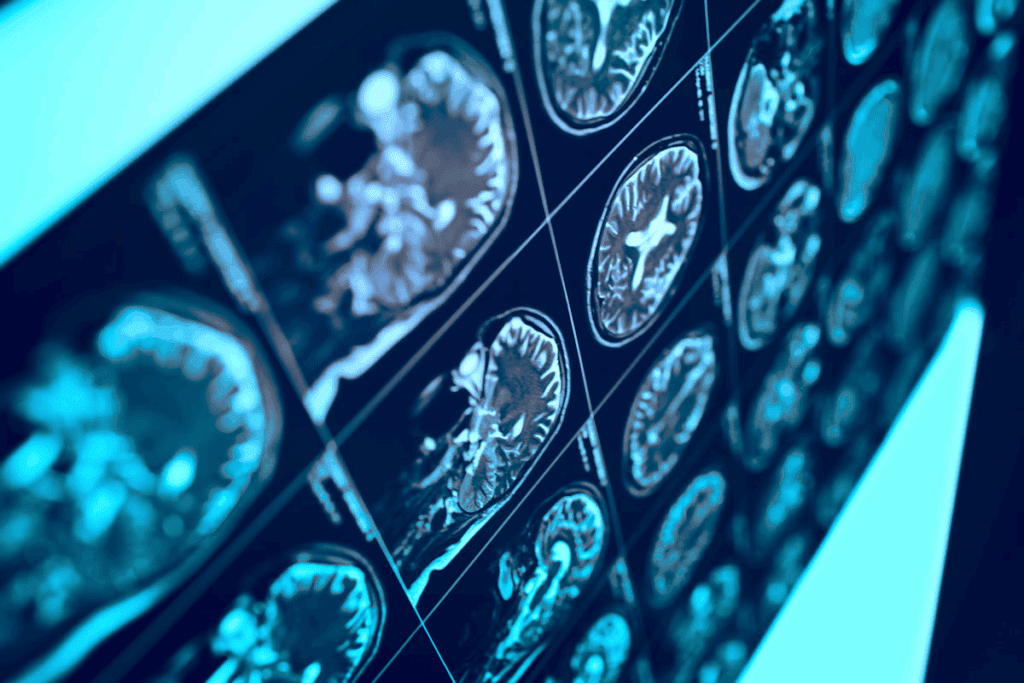

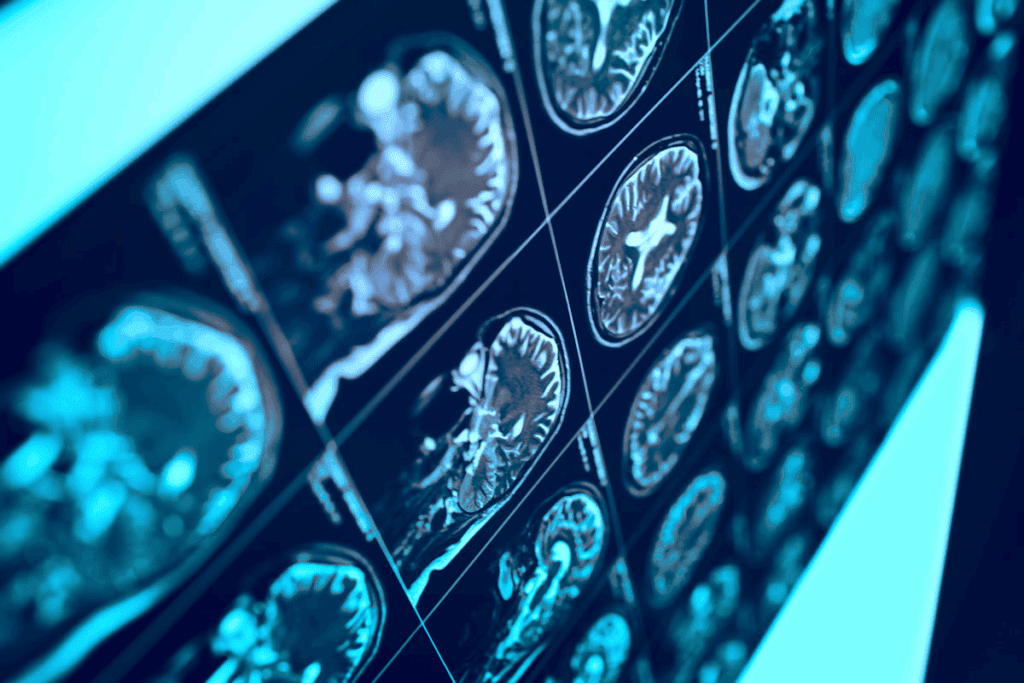

Medical infrared thermography turns body temperature into pictures. It’s used in many health areas, like cancer, pain, inflammation, and blood vessel problems.

Transition from Conventional to IR-Based Injection Methods

The switch to IR-based injection methods came from wanting more precision, safety, and efficiency. IR-based polymer molding has changed industrial making, making better products with less energy.

In health, IR-assisted injections are showing good results. They help with pain, are more accurate, and speed up healing. Studies have shown IR technology’s benefits in healing wounds, skin care, pain relief, and treating long-term diseases.

Current State of IR Technology in Healthcare and Manufacturing

Now, IR technology is used in health for checking and treating, and in making for things like injection molding and material handling. Today’s IR tech has better temperature control and uses less energy.

IR technology has made medical and industrial processes more precise and accurate. As we keep improving IR technology, we’ll see new uses in health and making.

Understanding the Science Behind IR Injection

To understand IR injection, we need to know the science behind it. IR technology is key in both medicine and industry, mainly in injection processes. It works by using different infrared wavelengths, each with its own uses.

Near vs. Far Infrared Wavelengths and Their Properties

Infrared radiation is split into near-infrared (NIR) and far-infrared (FIR) based on wavelength. NIR has a shorter wavelength, from 0.75 to 1.4 micrometers. It’s great for medical uses because it goes deep into tissue.

FIR has a longer wavelength, from 3 to 1000 micrometers. It’s mainly for heating because it’s absorbed by water and other materials, creating heat.

The wavelengths’ properties decide their uses. NIR is good for medical imaging because it goes deep. FIR is used in industrial heating.

Thermal Imaging Principles in Medical Applications

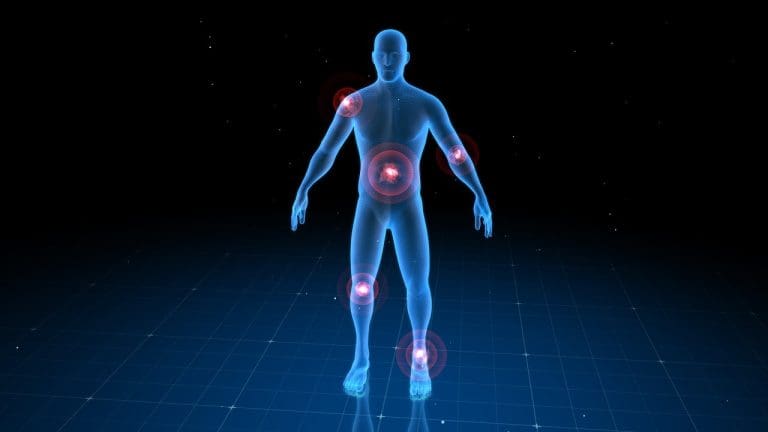

Thermal imaging uses IR radiation to spot temperature changes. It shows these changes as thermal images, with colors showing temperature levels. This helps find tissue problems, pick the best injection sites, and watch inflammation in real time.

| Application | Benefits | IR Wavelength Used |

| Medical Diagnostics | Deep tissue penetration, precise detection of abnormalities | Near-Infrared (NIR) |

| Industrial Heating | Efficient heating, improved product quality | Far-Infrared (FIR) |

Heat Transfer Mechanisms in Industrial Injection Molding

In injection molding, knowing how heat moves is key to better products. IR technology heats materials evenly. This ensures plastic melts well and consistently.

IR technology also makes faster cycle times and precision molding possible. This boosts production speed and cuts energy use. It helps manufacturers make big improvements in their work.

Advantage #1: Enhanced Precision and Accuracy in Injection Procedures

Infrared (IR) technology has changed the game in medical and industrial fields. It boosts precision and accuracy in injection processes. This is key for medical injections and industrial polymer processing, where accuracy matters a lot.

Real-Time Tissue Visualization for Medical Injections

IR technology lets doctors see tissues in real-time during medical injections. This helps them target the right area for treatment. It’s super important for both the success and safety of the procedure.

IR thermography spots changes in tissues before they show up as lesions. This helps doctors diagnose and treat early. They can see thermal patterns to choose the best injection site and method.

Optimized Injection Site Selection Through Thermal Mapping

Thermal mapping with IR technology helps pick the best injection sites. Doctors can see thermal patterns to find the safest and most effective spots. This reduces risks and improves results for patients.

This tech is great for procedures where tissue heat shows inflammation or other issues. It helps doctors make better choices for injections.

Precision Control in Industrial Polymer Processing

In industry, IR heating systems control the heat in polymer processing with great precision. This is vital for consistent product quality and less waste.

Using advanced IR systems in injection molding leads to uniform heating. This is key for making high-quality polymers. IR beats traditional heating in energy use and product consistency.

IR technology also lets manufacturers control temperatures precisely. This is hard to do with old heating methods. It’s essential for the quality of the final product.

Advantage #2: Improved Safety Profiles of IR-Assisted Injections

IR-assisted injections are safer because they don’t hurt the skin. This is thanks to infrared technology. It makes both medical and industrial processes safer.

Non-Invasive Monitoring Capabilities

IR technology lets doctors watch tissue temperature in real-time. This helps spot problems early. It’s a safe way to treat patients.

Real-time monitoring is key in medical care. It lets doctors make quick changes to help patients. IR imaging finds tissue issues fast, which is important for treatment.

Real-Time Detection of Inflammatory Responses

IR-assisted injections can spot inflammation right away. This is important because it shows how the body reacts to the injection. Catching it early helps avoid bigger problems.

Medical infrared thermography finds temperature changes that show health issues. Doctors can then change treatments to avoid bad reactions.

Reduced Risk of Tissue Damage

IR technology makes injections safer by being more precise. It helps avoid nerve or blood vessel damage. This makes injections safer for patients.

In factories, IR technology also makes things safer. It controls heat better, cutting down on accidents. The benefits of infrared injection processes are clear in both fields.

Safety Enhancements in Industrial Applications

In injection molding, IR technology keeps temperatures right. This makes products better. It also saves money and is better for the environment.

| Safety Aspect | IR-Assisted Injections | Traditional Methods |

| Non-Invasive Monitoring | Real-time thermal imaging | Limited real-time feedback |

| Risk of Tissue Damage | Reduced risk due to precision | Higher risk of complications |

| Inflammatory Response Detection | Early detection through IR thermography | Delayed detection |

The table shows how IR-assisted injections are safer than old methods. It shows the benefits in both medical and industrial settings.

Advantage #3: Significant Pain Reduction in Medical IR Injection Procedures

Infrared (IR) technology has changed medical injections by making them less painful. Now, doctors use IR to make injections more comfortable for patients.

Neurological Mechanisms Behind IR Pain Reduction

IR technology works by stimulating nerves that help reduce pain. It does this by calming the nervous system, making pain less intense.

Research shows IR can release natural pain fighters in the body. This helps patients feel less pain during IR-assisted injections.

Clinical Studies on Patient Comfort

Studies prove IR technology makes injections more comfortable. Clinical trials show patients feel less pain with IR-assisted injections than traditional ones.

More research is coming out on IR’s benefits in medicine. It shows IR can reduce pain and improve patient results. Using IR in medicine is a big step forward for patient care.

Comparative Analysis with Traditional Injection Methods

IR-assisted injections are better than traditional ones. Traditional injections can be more painful because they use mechanical or chemical methods.

IR injections are non-invasive and gentle. They cause less tissue damage and are more comfortable for patients. Advanced IR heating systems make these procedures even more precise and effective.

Using IR technology, doctors can make injections less painful. This helps improve patient care and outcomes.

Advantage #4: Energy Efficiency and Cost Effectiveness

IR technology helps industries save a lot of money by using less energy. It changes how we do things in medicine and industry. Now, we have more efficient and cheaper ways to do things.

Reduced Energy Consumption in Industrial IR Injection Processes

IR heating cuts down energy use in industrial injection. It does this by delivering heat precisely, wasting less and making more. Infrared lamps are great because they heat up consistently and well.

IR technology in making polymers also cuts energy costs. For example, a study found that IR-based polymer molding saves up to 30% energy compared to old methods.

Faster Cycle Times and Increased Production Efficiency

IR technology makes industrial injection molding faster. It heats and cools materials quickly. This means production lines work better, making more without losing quality.

| Process | Traditional Method | IR Technology |

| Heating Time | 10 minutes | 5 minutes |

| Cooling Time | 8 minutes | 4 minutes |

| Total Cycle Time | 18 minutes | 9 minutes |

Long-Term Cost Benefits for Healthcare Facilities

Healthcare gets big savings from IR technology over time. It cuts down on the need for extra equipment and makes patients better faster. This makes IR technology a smart choice.

Healthcare places that use IR technology see lower costs as time goes on. This is because they need fewer repeat procedures and can treat patients better.

Advantage #5: Accelerated Healing and Therapeutic Benefits

Infrared (IR) technology in injection processes speeds up healing and offers many benefits. IR-assisted injections are useful in both medical and industrial fields. They provide advantages that go beyond the injection itself.

Promotion of Circulation Through IR Technology

IR technology helps improve blood flow. This means more oxygen and nutrients reach the affected area. It supports healing by removing waste and reducing complications.

Anti-Inflammatory Effects on Injected Tissues

IR technology also reduces inflammation in tissues. This is great for injection procedures. It helps avoid tissue damage and supports healing.

Support for Mitochondrial Activity and Cellular Regeneration

IR radiation boosts mitochondrial activity. This is key for energy production and cell repair. It leads to better tissue health and function.

Applications in Chronic Disease Management

IR technology is good for managing chronic diseases. Conditions like arthritis and diabetes can benefit from its effects. It offers a more effective treatment option.

In conclusion, IR technology in injection processes has many benefits. It improves circulation, reduces inflammation, and supports cell repair. It’s a big step forward in medical and industrial fields.

Clinical Applications of IR Injection Technology

IR injection technology is changing many medical fields. It brings new ways to treat patients and improve care. As we learn more about IR technology, its benefits in different areas become clearer.

Wound Healing Protocols

IR technology helps in wound healing by improving tissue repair and lowering infection risk. Near and far infrared modalities boost circulation, key for healing. Research shows IR treatments can speed up wound closure and cut recovery time.

Medical infrared thermography, linked to IR technology, is used in fields like oncology and rheumatology. It detects temperature changes. This helps track wound healing and spot problems early.

Dermatological Treatments

In dermatology, IR treatments enhance skin health and lessen scar appearance. IR radiation boosts collagen, making skin more elastic and smooth. This method is a gentle alternative to surgery.

Pain Management Therapies

IR technology is a non-invasive pain relief option, reducing need for drugs. It improves circulation and lowers inflammation. This helps those with chronic pain find relief.

Chronic Disease Interventions

IR-assisted injections are being studied for managing chronic diseases like diabetes and arthritis. IR technology can reduce inflammation and aid healing. These are key in managing these conditions.

| Clinical Application | Benefits | Potential Outcomes |

| Wound Healing | Enhanced tissue repair, reduced infection risk | Faster wound closure, reduced recovery time |

| Dermatological Treatments | Improved skin health, reduced scarring | Enhanced skin elasticity, texture improvement |

| Pain Management | Non-invasive, reduced pharmaceutical reliance | Significant pain relief, improved quality of life |

| Chronic Disease Management | Reduced inflammation, promoted healing | Better disease management, improved patient outcomes |

As IR injection technology grows, its uses in medicine will expand. It will open new ways to treat patients and enhance care in many fields.

Industrial Implementation of IR Technology in Plastic Injection Molding

IR technology has made plastic injection molding more precise and energy-efficient. This change is big in the manufacturing world, with IR technology leading the way in plastic injection molding.

Advanced IR Heating Systems for Polymer Processing

Advanced IR heating systems are key in this change. They give precise control over the heating process. This means the polymer materials are heated evenly, making products better and wasting less material.

The IR technology also lets us monitor temperatures in real-time. This is very important for keeping the right temperature for different materials.

Temperature Control Mechanisms in Production

Keeping the right temperature is very important in plastic injection molding. IR technology helps with this by giving advanced temperature control. This makes products better and makes production more efficient.

By keeping temperatures just right, makers can avoid mistakes and make products more consistent.

Case Studies: Successful Industrial Applications

Many case studies show how IR technology works well in plastic injection molding. For example, a big maker of plastic parts used IR heating to get better at making things. They used less energy and made products that were better.

These stories show how IR technology can change how things are made. As it gets better, we’ll see even more new ways to use it.

Conclusion: The Future of IR Injection in Healthcare and Manufacturing

As we keep using infrared technology, we’ll see big improvements in health care and making things. At Liv Hospital, we’re dedicated to top-notch health care. We think IR technology will be key to reaching our goals.

IR injection technology has many benefits. It’s precise, safe, and saves energy. It’s great for both health care and making things. Infrared thermography is also useful in many areas, showing IR technology’s wide range of uses.

Using IR injection technology helps blood flow, cuts down inflammation, and boosts mitochondria. This leads to faster healing and better health benefits. As we go on, IR technology will be more important in health care and making things. It will help drive new ideas and excellence in these areas.

FAQ

What is Infrared (IR) technology, and how is it used in injection processes?

IR technology uses infrared radiation for non-invasive thermal imaging and therapy. It’s changing how we do injections in medicine and industry.

How does IR technology enhance precision and accuracy in medical injections?

IR technology lets doctors see tissues in real-time. This helps them aim treatments better, cutting down on risks and improving results.

What are the benefits of IR technology in industrial polymer processing?

IR heating systems offer precise heat control. This leads to better products and less waste.

How does IR technology improve safety in medical and industrial injection processes?

IR technology lets us monitor without touching. It spots inflammation early and keeps tissues safe. It also controls heat well in factories.

Can IR technology reduce pain in medical injection procedures?

Yes, IR technology can lessen pain. It works by stimulating nerves that help reduce pain feeling.

What are the energy efficiency benefits of IR technology in industrial IR injection processes?

IR technology cuts down energy use and boosts efficiency. This means faster production and lower costs.

How does IR technology accelerate healing and provide therapeutic benefits?

IR technology boosts blood flow, lowers swelling, and helps cells work better. This greatly improves health and offers hope for chronic disease patients.

What are the clinical applications of IR injection technology?

IR technology is used for wound care, skin treatments, pain relief, and fighting chronic diseases. It offers many benefits for patients.

How is IR technology implemented in plastic injection molding?

IR heating systems control heat precisely in plastic molding. This results in better products and less waste. It’s shown to work well in many cases.

What is the future of IR injection technology in healthcare and manufacturing?

IR injection technology will keep getting better. It will lead to better health outcomes and more efficient production. It has a bright future in both fields.