Robots can perform tasks with a precision that is up to 10 times higher than that of humans. This amazing accuracy is changing many industries, from making things to helping in healthcare.

When we ask if robots are more precise than humans, we look at the benefits of robot technology. Robots have special designs that let them move and act with high precision. This makes them perfect for jobs that need exactness.

We dive into what robots are, their mechanical benefits, and how they’re used in different fields. We see how they beat humans in precision.

Key Takeaways

- Robots can achieve precision up to 10 times higher than humans.

- Robotic technology is transforming industries with its accuracy.

- The mechanical design of robots enables precise movements.

- Robots are ideal for tasks requiring high precision.

- Robot precision has significant implications for the future of work.

What Are Robots: Definition and Core Components

Robots are complex machines that can do many tasks. They are often more precise and efficient than humans. To understand robots, we need to look at their core parts and the technology that makes them work.

The Evolution of Robotics Technology

Robotics technology has changed a lot over the years. It has moved from simple machines to advanced ones. The use of artificial intelligence (AI) and machine learning (ML) has been key in this change. These technologies let robots learn and get better over time.

Experto AI Inc. on talks about how AI is important for robots. It helps them understand and adapt to their surroundings better.

Essential Components That Enable Robot Precision

Several parts are key to a robot’s precision. These include sensors, actuators, and control systems. Sensors help robots see their environment. Actuators let them move and do tasks. The control system makes sure everything works together smoothly.

- Sensors: Provide environmental data

- Actuators: Enable movement and task execution

- Control Systems: Integrate data and commands for precision

Types of Robots and Their Precision Capabilities

There are many types of robots, each for different tasks and industries. Industrial robots are used a lot in manufacturing for tasks like assembly and welding. Service robots help humans in places like healthcare and homes.

Precision varies among robot types. Some are made for very precise tasks like microassembly. Others are better at tasks that need flexibility and adaptability.

|

Robot Type |

Precision Capability |

|---|---|

|

Industrial Robots |

High precision in assembly and welding |

|

Service Robots |

Varied precision depending on task |

Human Precision: Capabilities and Limitations

The human ability to do tasks with precision is complex. It’s not just about physical skills. It also involves thinking and adapting to different situations.

The Remarkable Precision of Human Hands and Eyes

Human hands and eyes are incredibly precise. Hands can do delicate tasks like surgery or making fine jewelry. Eyes help guide these precise movements by seeing small differences in color and shape.

The way hands and eyes work together lets us do tasks like threading a needle or microsurgery. This teamwork is thanks to the brain, muscles, and sensory feedback.

Cognitive Factors in Human Precision Tasks

Cognitive factors greatly affect human precision. Attention, focus, and making decisions are key. For example, a surgeon’s ability to concentrate is as important as their hand skills.

Experience and training also improve cognitive factors, leading to better precision over time. This is seen in how professionals, like craftsmen or surgeons, get better with practice.

Fatigue and Consistency Issues in Human Performance

Despite our amazing precision, there are limits, like fatigue and consistency. Fatigue can make us less precise as we work longer. Consistency is also a challenge, as our performance can change due to mood, health, and environment.

|

Factor |

Impact on Precision |

Mitigation Strategy |

|---|---|---|

|

Fatigue |

Decreases precision over time |

Regular breaks, task rotation |

|

Cognitive Load |

Affects decision-making and focus |

Training, experience, simplifying tasks |

|

Environmental Conditions |

Variations in lighting, noise, etc., can impact precision |

Optimizing work environment, using protective gear |

Knowing these limits helps us see why robots and automation are important. They help improve precision and consistency in many tasks.

Robot Precision: Mechanical Advantages

Robots are known for their unmatched precision. This is due to their mechanical design and capabilities. Robots can perform tasks with great accuracy and repeatability.

Repeatability vs. Accuracy in Robotics

In robotics, repeatability means a robot can go back to the same spot over and over. Accuracy is about how close the robot is to its intended spot. Both are key for precise robotic tasks.

“The difference between repeatability and accuracy is key to understanding robot precision,” experts say. “A robot can be very repeatable but not accurate if it’s not programmed right.”

How Robot Programming Enhances Precision

Robot programming is essential for precision. Advanced programming lets robots adjust their movements in real-time. This is vital for tasks like welding or assembly.

Today’s robots have advanced control systems for precise movements. These systems use algorithms to make sure the robot stays on track.

Sensor Technology and Feedback Systems

Sensors and feedback systems are vital for robot precision. Sensors give real-time data on the robot’s surroundings and state. Feedback systems use this data to adjust the robot’s path.

The use of sensors and feedback has greatly improved robot precision. A report says, “advanced sensors and feedback have made robots essential in industries needing high accuracy.”

- Advanced sensor technology provides real-time data.

- Feedback systems correct the robot’s movements.

- Integration enhances overall precision and reliability.

Comparative Analysis: Robots vs. Humans in Manufacturing

As manufacturing gets more automated, knowing how robots and humans compare is key. We look at their strengths and weaknesses in precision assembly and quality control. We also explore the balance between speed and precision.

Precision Assembly and Quality Control

Robots have changed precision assembly in manufacturing by being consistent and accurate. In tasks needing tiny precision, like electronics assembly, robots beat humans. They can keep focus and precision for a long time.

In making microchips, robots handle delicate parts with precision, cutting down on defects and improving quality. Humans can’t match this level of precision consistently, mainly in big production settings.

Speed vs. Precision Trade-offs

Robots are great at precision but can be slow. Humans are quick to learn new tasks but may not be as precise. The choice between speed and precision is key in manufacturing, affecting both productivity and quality.

In fast-paced tasks, like car manufacturing, robots can work quickly and precisely. But for tasks needing flexibility and adaptability, humans might be better, even with less precision.

Economic Implications of Robot Precision

The economic effects of using robots for precise tasks in manufacturing are complex. The cost of buying robots is high upfront. But, the long-term savings, like lower labor costs and better product quality, can be huge.

Robots also help reduce costs from human mistakes, like rework and waste. They make manufacturing more efficient, boosting profits.

Robotics in Industries: Precision-Critical Applications

Robotics are changing industries like automotive, electronics, and pharmaceuticals. They help make products better, cheaper, and more precise. This is thanks to their ability to work with high precision.

Automotive Manufacturing Precision

In car making, robots do jobs that need a lot of precision. Robotic arms with advanced sensors and vision systems help with welding and assembly. This ensures parts fit together perfectly.

Robots have made car making better and more consistent. They can do tasks over and over again without mistakes. This means cars are made with higher quality and less error.

|

Task |

Precision Level |

Benefits |

|---|---|---|

|

Welding |

High |

Consistent weld quality |

|

Assembly |

High |

Accurate part fitting |

|

Inspection |

High |

Early defect detection |

Electronics Assembly and Microchip Production

In electronics, robots are key for making microchips and other parts. They can handle tiny things with micron-level precision. This ensures products meet high standards.

Robots help make smaller, more complex electronics. This has led to the creation of compact, high-performance devices. It’s a big step forward in consumer electronics.

Pharmaceutical and Medical Device Manufacturing

Robotics also help in making medicines and medical devices. In medical device making, high precision is critical. It’s important for device function and patient safety.

In making medicines, robots help with packaging and labeling. Precision is key here to avoid mistakes and follow rules.

Medical Robotics: When Precision Saves Lives

Medical robotics is more than just tech; it’s a lifesaver in surgery. It has changed healthcare by making surgeries more precise, cutting down recovery times, and improving patient results. We’ll look at how robotic systems play a key role in medical care, focusing on their precision and how it helps patients.

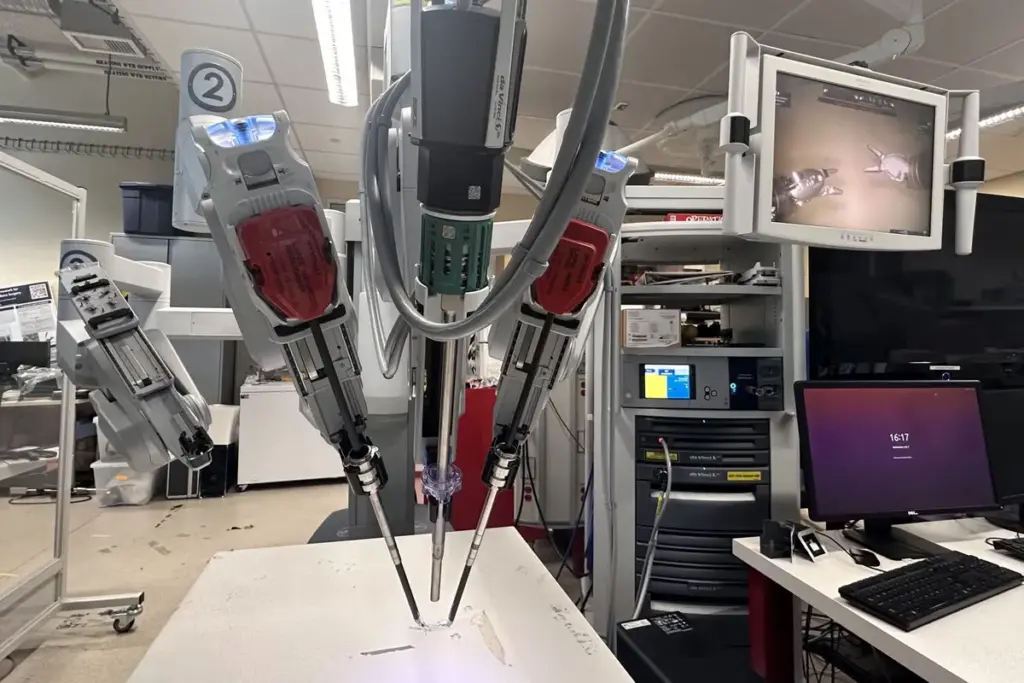

Surgical Robots and Their Precision Capabilities

Surgical robots have changed the operating room. They give surgeons better precision, flexibility, and control. These robots have high-definition 3D vision and instruments that can move in ways humans can’t.

This allows for more accurate surgeries, like neurosurgery and microsurgery. These are surgeries where small mistakes can be very dangerous. Thanks to robots, surgeons can do their jobs more accurately, which means better results for patients.

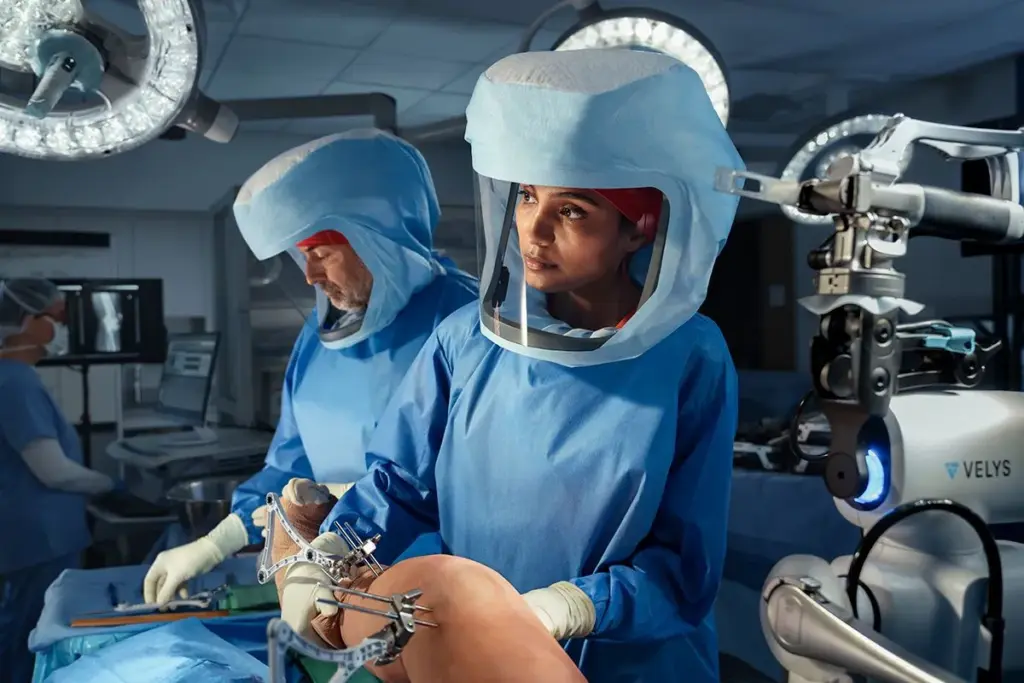

Human Surgeons vs. Robotic Systems: A Precision Comparison

Human surgeons are incredibly skilled, but robots can be even more precise. Robots don’t get tired or shaky like humans do, so they can work perfectly for hours. This is a big advantage in long surgeries.

Research shows that robotic surgery can lead to fewer problems and less blood loss than traditional surgery. But it’s important to remember that robots are tools that help surgeons, not replace them.

Patient Outcomes and Recovery Metrics

Using medical robotics in surgery has greatly improved patient care and recovery. Patients often feel less pain, have smaller scars, and stay in the hospital less time. This means they can get back to their lives faster and are less likely to get infections in the hospital.

Also, robotic surgery can mean fewer complications after surgery. This leads to fewer times patients have to go back to the hospital. As medical robotics keeps getting better, we can expect even better results in the future.

Ways Robots Are Used in Daily Life: Precision Applications

Robots are now a big part of our daily lives. They do many tasks with great precision. From cleaning our homes to helping with navigation, robots make things more efficient and accurate.

Smart Home Robots and Precision Tasks

Smart home robots are changing how we manage our homes. They do tasks like cleaning, cooking, and maintenance with great precision. These robots have advanced sensors and AI that help them move and interact with their surroundings.

For example, robotic vacuum cleaners can map out a home and clean it well. They avoid obstacles and make sure every spot is clean.

Self-Driving Vehicles and Navigational Precision

Self-driving vehicles are a big step forward in robotics. They need to navigate roads with precision to be safe and efficient. These vehicles use sensors, GPS, and AI to move around, recognize traffic signals, and avoid accidents.

Their precision is key to making quick decisions and adapting to changing road conditions. This makes roads safer and reduces the chance of accidents.

Delivery and Service Robots

Delivery and service robots are used in many areas, like logistics, healthcare, and customer service. They can navigate through complex places, like busy streets or hospital corridors, with ease. They have advanced navigation systems and sensors to avoid obstacles and get to their destinations quickly.

In healthcare, for example, robots help deliver medication and supplies. This reduces the workload of healthcare staff and makes responses faster.

We’re seeing a big change in how robots are used in our daily lives. Precision is a key factor in their success. As technology gets better, we’ll see even more creative uses of robots in our homes, on the roads, and in healthcare and service industries.

The Human Touch: Areas Where Human Precision Stills Dominates

Human precision is key in many fields where creativity and flexibility are important. Robots have made great strides in precision tasks. Yet, there are areas where only humans can truly shine.

Creative Industries and Craftsmanship

In creative fields like art, craft, and design, human precision is more than just accuracy. It’s about creativity and originality. Craftsmanship requires a personal touch that machines can’t match. Skilled artisans create pieces that are both beautiful and functional.

Humans bring a unique touch to these industries. For example, a skilled furniture maker can turn a piece of furniture into a work of art. This shows the maker’s creativity and personal style.

Contextual Decision-Making and Adaptability

Human precision is vital for contextual decision-making and being adaptable. Humans can make quick, nuanced decisions in changing environments. This is very important in fields like healthcare, where professionals must act fast.

In surgeries, for instance, surgeons must adjust their techniques on the fly. This adaptability is something robots can’t do yet. It shows how important human precision is in critical situations.

Complex Environmental Navigation

Navigating complex environments is another area where humans excel. We can move through cluttered or unpredictable spaces with ease. This skill is vital in many areas, like search and rescue or navigating crowded cities.

Understanding and navigating complex environments is not just about moving. It’s about making sense of the space and adjusting as needed. Humans use their senses and experience to navigate these spaces. Robots are not yet able to do this with the same precision and flexibility.

Advantages of Robots Beyond Precision

Robots do more than just precise work. They also boost safety, increase productivity, and handle dangerous tasks. As more industries use robots, these benefits grow. They make work safer and more efficient.

Safety Improvements Through Robotic Automation

Robots make many places safer. They take on tasks that are too risky for people. For example, in factories, robots lift heavy things and work in hot or toxic areas. This keeps workers safe.

Studies show robots have cut down on workplace dangers. By doing risky jobs, robots protect people. They also make the workplace safer for everyone.

Productivity and Efficiency Gains

Robots also make work faster and better. They work without getting tired and are very precise. This means they can make more products of higher quality.

In factories, robots work all the time. This means more products and less time waiting. Robots can also work with AI and machine learning. This makes production even better by monitoring and adjusting things in real time.

Handling Hazardous Tasks and Environments

Robots are great at doing jobs that are too dangerous for people. They handle radioactive stuff, extreme temperatures, and dirty places. This keeps humans safe.

In places like nuclear plants, chemical factories, and space, robots are key. They do jobs that are too risky for people. This makes these places safer and lets important tasks get done.

Limitations of Robot Precision

Robots have many benefits, but they also face some challenges. They help a lot in making things and improving how we work. Yet, their performance can be affected by several things.

Environmental Factors Affecting Robot Performance

Things like temperature, humidity, and vibrations can mess with a robot’s accuracy. For example, when it’s very hot, parts can expand and make the robot less precise.

Table: Environmental Factors Impacting Robot Precision

|

Environmental Factor |

Impact on Robot Precision |

Mitigation Strategy |

|---|---|---|

|

Temperature Fluctuations |

Component expansion/contraction affecting accuracy |

Temperature-controlled environments |

|

Humidity |

Corrosion of components, electrical issues |

Climate-controlled facilities |

|

Vibrations |

Mechanical stress on robot structures |

Vibration-damping mounts |

Maintenance Requirements for Maintaining Precision

Keeping robots in top shape is key. Parts can wear out, software can glitch, and calibration can drift. Regular checks and updates are needed to keep them precise.

Cost Barriers to High-Precision Robotics

High-precision robots are pricey. They come with advanced sensors and AI, which adds to the cost. You also have to think about maintenance, training, and downtime.

But, the benefits of better precision and work efficiency might make the cost worth it. Often, the long-term gains outweigh the initial investment.

How Can Robots Help Humans: Collaborative Precision

Collaborative robots, or cobots, are changing how we work. They mix human flexibility with robotic precision. This mix boosts productivity and work quality in many fields.

Cobots: Combining Human Flexibility with Robot Precision

Cobots work alongside humans, using their best qualities for complex tasks. They have advanced sensors and programming to adjust to changing situations.

In manufacturing, cobots help with tasks that are repetitive or dangerous. This lets humans do more creative and complex work. It makes work more efficient and safer.

Augmenting Human Capabilities with Robotic Tools

Robotic tools are used to improve human abilities, mainly for tasks needing high precision. Exoskeletons, for example, boost human physical strength, making tasks easier or possible.

|

Robotic Tool |

Human Capability Enhanced |

Industry Application |

|---|---|---|

|

Exoskeletons |

Physical Strength and Endurance |

Manufacturing, Construction |

|

Precision Assembly Robots |

Fine Motor Skills and Accuracy |

Electronics, Automotive |

|

Robotic Assistants |

Cognitive Load and Task Management |

Healthcare, Logistics |

Training and Skill Development for Human-Robot Teams

As humans and robots team up more, training is key. Training programs teach workers to work well with robots, ensuring smooth teamwork.

These programs improve skills like problem-solving and adaptability. By combining human skills with robotic precision, industries can innovate and produce more.

The Future of Robotics Technology and Precision

The future of robotics is set to change many industries with better precision and skills. We’re exploring new ways for robots to do more. Several key areas are important for the next big steps in robotics.

Advances in Sensors and Feedback Systems

Improvements in sensors and feedback systems are key for robotics. These help robots see and adjust to their surroundings better. Enhanced sensor capabilities mean robots can handle delicate tasks more accurately.

Feedback systems, like visual and tactile feedback, are essential. They help robots adapt to new situations. For example, better computer vision lets robots sort and assemble more accurately.

AI and Machine Learning for Enhanced Precision

Artificial intelligence (AI) and machine learning (ML) are changing robotics. They let robots learn and get better over time. Machine learning algorithms improve robot performance and predict when they need maintenance.

AI also makes robots better at working with humans. Robots can understand human actions and adapt, making tasks more efficient.

Biomimetic Approaches to Robot Precision

Biomimetics, inspired by nature, is driving robotics innovation. It helps create robots that are more precise and adaptable. By studying nature, researchers make robots that can do complex tasks.

For instance, robotic hands that mimic human hands are being developed. These can do tasks that require fine motor skills, like surgery or assembling small parts.

Looking ahead, combining sensor advancements, AI, ML, and biomimetics will greatly improve robot precision. These improvements will make robots more useful in manufacturing and healthcare. They will also open up new possibilities in other industries.

Conclusion: The Complementary Nature of Human and Robot Precision

We’ve looked into whether robots are more precise than humans. We’ve seen the good and bad of both. It’s clear that humans and robots work well together, each bringing their own strengths.

Knowing what humans and robots can do helps us use them better in many fields. This includes making things, helping in healthcare, and in our daily lives. Robots’ precision can be matched with humans’ ability to adapt, leading to better results.

The future of robots looks bright, with new tech like sensors, AI, and machine learning on the horizon. These advancements will make robots even more precise. As we keep improving these technologies, humans and robots will work together more effectively.

FAQ

What is a robot and how does it work?

A robot is a machine that does specific tasks. It uses sensors, actuators, and control systems. These help it move and act with precision in its environment.

What are the core components that enable robot precision?

The key parts for robot precision are sensors, actuators, and control systems. Together, they ensure robots move accurately and consistently.

How do robots compare to humans in terms of precision?

Robots are more precise than humans in repetitive tasks. But, humans are better at tasks that need adaptability and making decisions based on context.

What are the advantages of using robots in manufacturing?

Robots bring many benefits to manufacturing. They improve precision, boost productivity, and make the work environment safer. They can also handle dangerous tasks.

What are some examples of precision-critical applications of robotics?

Robots are vital in tasks like making cars, assembling electronics, and creating medical devices. These areas need high precision to ensure quality.

How do surgical robots improve patient outcomes?

Surgical robots help by giving surgeons better control and precision. This leads to less invasive surgeries, shorter recovery times, and more accurate results.

What are cobots and how do they enhance human-robot collaboration?

Cobots, or collaborative robots, work alongside humans. They combine robot precision with human flexibility. This boosts productivity and efficiency.

What are some limitations of robot precision?

Robot precision can be limited by environmental factors and the need for maintenance. High-precision robots can also be expensive.

How will advances in AI and machine learning impact robot precision?

AI and machine learning will help robots learn and adapt. This will improve their precision over time, making them more capable.

What are some future applications of robotics technology?

Future robotics will be used in advanced manufacturing, healthcare, and service areas. Robots will perform complex tasks, increase productivity, and enhance quality of life.

What is the role of sensors and feedback systems in achieving high-precision robotics?

Sensors and feedback systems are essential for high-precision robotics. They provide real-time data, allowing robots to adjust their actions for better performance.

How can humans and robots work together effectively?

Humans and robots can work well together. Humans handle tasks that require adaptability and decision-making. Robots focus on precision and repetition.

References

National Center for Biotechnology Information. Evidence-Based Medical Insight. Retrieved from https://pubmed.ncbi.nlm.nih.gov/29958710/