Choosing the right material for knee replacement is key for long-term health and happiness. At Liv Hospital, we focus on quality, ethics, and patient care.

Cobalt chrome and titanium are top choices for knee replacement. They are durable and safe for the body. But knowing their differences is important for the right choice.

We offer top-notch healthcare for international patients. Our team helps you understand the pros and cons of knee replacement materials. We aim to find the best fit for you.

Key Takeaways

- Understanding the differences between knee replacement materials is key for making an informed decision.

- Cobalt chrome and titanium are two of the most common metals used in knee replacement procedures.

- Both materials offer high durability and biocompatibility.

- The choice of material impacts long-term mobility, comfort, and quality of life.

- Liv Hospital provides world-class healthcare with complete support for international patients.

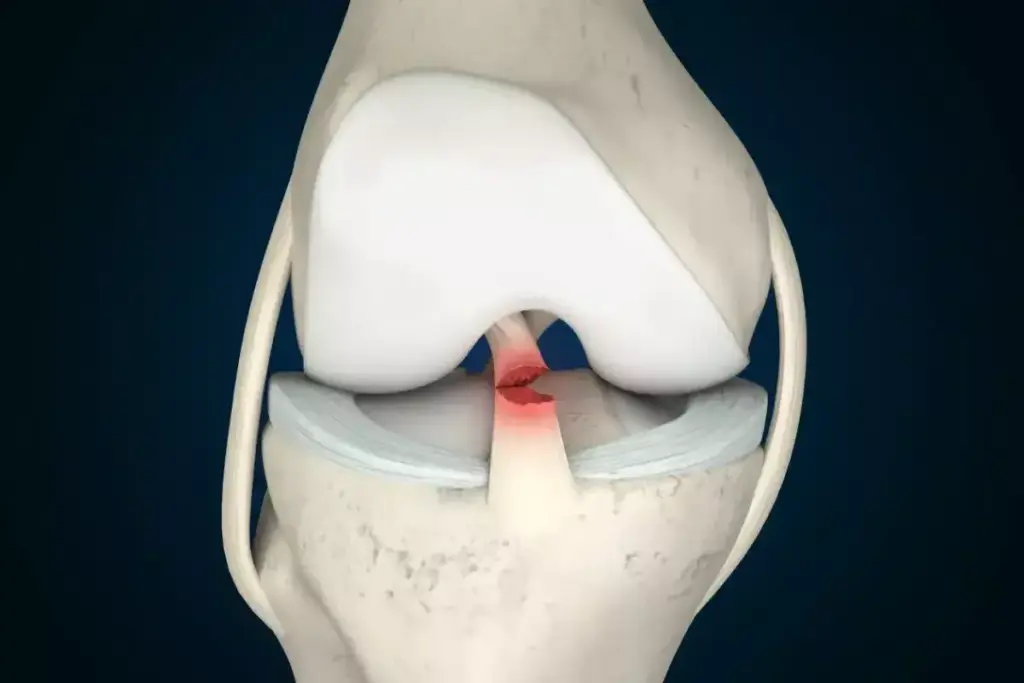

The Science Behind Modern Knee Replacement Materials

It’s important to know how knee replacement materials work. These materials have changed a lot over time. This change is thanks to new technology and our better understanding of how they work with the body.

Evolution of Implant Materials in Orthopedic Surgery

Knee replacement materials have a long history. Early ones didn’t last long because of wear and corrosion. Modern materials are made to last longer and be safer for patients. A study on NCBI shows these new materials have greatly improved results for patients.

“The development of new materials and surface treatments has improved the longevity and functionality of knee replacements.”

How Material Properties Affect Patient Outcomes

The success of a knee replacement depends on the material’s durability, how well it works with the body, and how it holds up over time. For example, materials that don’t wear down quickly can make the implant last longer. Here’s a table comparing some key material properties.

| Material | Durability | Biocompatibility | Wear Resistance |

|---|---|---|---|

| Cobalt Chrome | High | Excellent | High |

| Titanium | High | Excellent | Moderate |

| Polyethylene | Moderate | Good | Moderate |

The right material can make a big difference in how well a knee replacement works. As we keep improving materials, we’ll see even better results for patients.

Cobalt Chrome vs Titanium Knee Replacement: Head-to-Head Comparison

Cobalt Chrome and Titanium are top choices for knee replacement surgery. Each has its own benefits and differences. Knowing these can help patients choose the best option for them.

Material Composition and Mechanical Properties

Cobalt Chrome is known for its strength and wear resistance. It’s made mainly of cobalt, chromium, and molybdenum. Titanium, on the other hand, is prized for its strength, lightness, and resistance to corrosion. It’s a mix of titanium, aluminum, and vanadium.

The mechanical properties of these materials are key. Cobalt Chrome’s hardness and wear resistance help prevent implant failure. Titanium’s flexibility and strength help reduce stress on the bone and encourage bone growth.

Weight and Biocompatibility Differences

Titanium is generally lighter than Cobalt Chrome, which is good for some patients. Both are biocompatible, but Cobalt Chrome has raised some metal ion release concerns. The clinical impact of this is not fully understood.

Clinical Studies on Long-term Performance

Many studies have looked at how Cobalt Chrome and Titanium knee replacements perform over time. These studies show both materials have great long-term survival rates. The results can vary based on the patient and the implant design.

| Material Property | Cobalt Chrome | Titanium |

|---|---|---|

| Wear Resistance | High | Moderate |

| Strength | High | High |

| Biocompatibility | Good | Excellent |

| Weight | Heavier | Lighter |

| Corrosion Resistance | High | High |

By looking at the properties and results of studies, doctors can choose the best material for each patient. This ensures the best fit for their needs.

Cobalt Chrome Knee Replacements: Strength and Durability Profile

Cobalt chrome knee replacements are getting a lot of attention in orthopedic surgery. They are known for their strength and durability. Choosing the right material for knee surgery is key, and cobalt chrome alloys are a top choice.

Superior Hardness and Wear Resistance Benefits

The hardness of cobalt chrome alloys makes them great for withstanding wear and tear. This is important for knee replacement parts that face a lot of stress and friction. These properties help lower the chance of implant failure and make the knee replacement last longer.

Also, cobalt chrome’s wear resistance helps reduce debris production. This can prevent osteolysis and implant loosening. Using cobalt chrome could mean fewer revision surgeries and better patient results.

Optimal Applications in Femoral Components

Cobalt chrome is perfect for femoral components because of its high strength and durability. We suggest cobalt chrome femoral components for active patients or those with a long life expectancy. These components can handle daily activities well and last longer.

Using cobalt chrome in femoral components also allows for thinner, more articulated designs. This can improve knee range of motion and function.

Addressing Concerns About Cobalt Ion Release

Even with the benefits, there are worries about cobalt ion release from these knee replacements. We know it’s important to watch for any bad reactions and take steps to prevent them.

Manufacturers have come up with better ways to make and treat the surface of these implants. This helps reduce ion release risk. We work with patients to keep an eye on their health and adjust treatment plans as needed for the best results.

Titanium Knee Replacements: Lightweight Performance Analysis

Lightweight titanium knee replacements are changing orthopedic surgery. They make patients move better. Titanium is strong, durable, and light. This makes patients more comfortable and mobile after surgery.

Advantages in Weight Reduction and Patient Mobility

Titanium knee replacements are light, which helps patients move better. Research shows they can move more and feel less tired. This is because the implant is lighter, putting less stress on bones and tissues.

Using titanium can help patients recover faster. It makes it easier for them to do everyday activities sooner. This is because titanium implants don’t strain the knee as much.

Bone Density Preservation Evidence

Titanium knee replacements also help keep bone density strong. They promote better bone growth and integration. This is key for the implant’s long-term success, as it lowers the chance of failure.

“The use of titanium in knee arthroplasty has been associated with favorable bone remodeling and density preservation, contributing to the longevity of the implant.”

Advancements in Surface Technology for Titanium Implants

New surface technologies have made titanium knee replacements even better. Techniques like porous coating and surface texturing help implants bond with bone. This has made titanium knee replacements last longer and work better.

There’s a move towards even more advanced surface technologies. These will help titanium implants integrate with the body better. As research goes on, we’ll see more ways to improve patient care.

Polyethylene Components: The Critical Articulating Surface

Polyethylene components are key to the success of knee replacement surgeries. The material used for the articulating surface has seen big improvements. These changes aim to make it last longer and work better.

Evolution of Plastic Materials in Joint Replacement

Plastic materials have been used in joint replacements for decades. At first, regular polyethylene was used, but it had its limits. Now, we have more advanced materials that last longer and wear less.

These new materials came from a need to make implants last longer and work better. So, highly cross-linked polyethylene is now a top choice for many knee replacements.

Highly Cross-linked Polyethylene: Reducing Wear Rates

Highly cross-linked polyethylene is a big step forward in knee replacements. It’s stronger and lasts longer than old polyethylene. This means implants can last longer and patients face fewer problems.

Research shows this material cuts down on wear debris. This is a big reason why implants don’t loosen or fail as often. So, patients are seeing better results from their knee surgeries.

Metal Sensitivity and Allergic Reactions in Knee Replacements

When thinking about knee replacement surgery, it’s key to know about metal sensitivity and allergic reactions. Metal sensitivity is a big worry for people getting orthopedic surgeries.

Identifying Patients at Risk for Metal Allergies

It’s important to find out who might have metal allergies before knee replacement. We look at a patient’s health history and past reactions to metals. A patch test can show if someone has a metal allergy.

Hypoallergenic Options for Sensitive Patients

For those with metal sensitivities, we have hypoallergenic options. These options include implants made from materials like ceramic or titanium alloys. They are safe and work well with the body.

| Material | Allergy Risk | Biocompatibility |

|---|---|---|

| Cobalt Chrome | Higher | Good |

| Titanium Alloy | Lower | Excellent |

| Ceramic | Lowest | Excellent |

Top 5 Material Choices for Knee Replacement Hardware

Choosing the right material for knee replacement hardware is key. It affects how long the implant lasts and how well it works. We’ll look at the top 5 materials used in knee surgery. We’ll talk about their benefits and when they’re best used.

1. Cobalt Chromium Alloys: Gold Standard for Wear Surfaces

Cobalt chromium alloys are the top choice for wear surfaces. They’re very hard and resistant to wear. This reduces the chance of the implant failing and makes movement smooth.

2. Titanium Alloys: Optimal for Tibial Components

Titanium alloys are great for tibial components. They’re strong, don’t corrode, and bond well with bone. This makes them perfect for those wanting a strong and lasting implant.

3. Highly Cross-linked Polyethylene: Advanced Bearing Surfaces

Highly cross-linked polyethylene is used for bearing surfaces. It’s very resistant to wear and lowers the risk of bone loss. This material has greatly increased the life of knee implants.

4. Ceramic Components: Alternative for Metal-Sensitive Patients

Ceramic components are a good option for those with metal allergies. They’re low-wear and safe, reducing the chance of bad reactions. This improves patient results.

5. Oxidized Zirconium: Hybrid Metal-Ceramic Technology

Oxidized zirconium is a mix of metal and ceramic. It’s very resistant to wear and has low friction. This makes it a great choice for those wanting a durable and smooth implant.

Knowing about these top 5 materials helps patients and doctors make better choices. It ensures the right knee replacement hardware is chosen for each person’s needs.

Personalized Selection Criteria for Knee Replacement Materials

Choosing the right knee replacement material is key for the best results and happiness. Every patient is different, and the material choice greatly affects surgery success.

Age-Based Considerations and Activity Level Assessment

Age and how active you are matter a lot when picking knee replacement materials. Young, active folks might do well with cobalt chrome for its toughness. Older or less active people might need other materials that last longer and wear less.

We look at how active you are to pick the best material for your life.

Medical History Factors and Allergy Testing

Your medical history is important in picking the right material. We think about past surgeries, health issues, and allergies. If you’re allergic to metals, we might suggest ceramic or titanium alloys.

Allergy tests help make sure the material won’t cause problems.

Collaborative Decision-Making with Your Orthopedic Team

Choosing the right material is a team effort between you and your doctors. We talk to you about what you need and want. By looking at all the factors and talking about the good and bad of each material, we make a choice that’s best for you.

For more on knee replacement materials, check out our knowledge hub.

Conclusion: Navigating Your Knee Replacement Material Options

Knowing the different materials for knee replacement is key. We’ve looked at Cobalt Chrome and Titanium, their special features, and advantages.

Choosing the right material is a big decision. It depends on your needs and situation. Think about how durable and safe the material is, and what you need personally.

The right knee replacement is one that fits your life and health. We suggest talking to your orthopedic team. They can help pick the best material for you.

This way, you get the best care and results from your surgery.

What are the most common materials used for knee replacement?

For knee replacements, cobalt chrome and titanium alloys are often used. Polyethylene is used as the surface that moves.

What is the difference between cobalt chrome and titanium knee replacements?

Cobalt chrome is hard and resists wear well. Titanium is light and safe for the body.

Are there any concerns related to cobalt ion release from cobalt chrome knee replacements?

Yes, there are worries about cobalt ions. But studies say the risks are low. The benefits of cobalt chrome usually outweigh the risks.

How does the material used for knee replacement affect patient outcomes?

The material affects how long the implant lasts and how well it works. It also affects the patient’s life quality. Durability, safety, and resistance to wear are key.

What is highly cross-linked polyethylene, and how does it benefit knee replacement?

Highly cross-linked polyethylene is a new material for knee replacements. It wears less and lasts longer. This means patients get a more durable implant.

Can metal sensitivity be a concern for knee replacement patients?

Yes, metal sensitivity is a worry. It’s important to find out who is at risk. There are hypoallergenic options for sensitive patients.

What are the top material choices for knee replacement hardware?

The best materials are cobalt chromium, titanium, and highly cross-linked polyethylene. Ceramic and oxidized zirconium are also good. Each has its own benefits.

How is the best knee replacement material chosen for an individual patient?

Choosing the right material depends on age, activity level, and medical history. Allergies are also checked. The patient and their doctor make this decision together.

What advancements have been made in surface technology for titanium implants?

Titanium implants have gotten better thanks to new surface technology. This improves how well they work with the body.

Are there any alternatives to traditional metal knee replacement materials?

Yes, there are alternatives like ceramic components. They are good for patients who are sensitive to metals.

References

- Healthline : https://www.healthline.com/health/total-knee-replacement-surgery/implant-manufacturers

- PMC – PubMed Central : https://www.ncbi.nlm.nih.gov/pmc/articles/PMC10375820

- PubMed : https://pubmed.ncbi.nlm.nih.gov/33349499