Medical Robotics and Robotic Surgery Systems 2025 Market Overview

This informational blog provides a high level overview of the medical robotics and automation ecosystem in 2025. It is written for educational purposes only and does not promote any specific product or service. As a hospital focused on patient safety and clinical excellence, we share neutral industry insights to help readers understand how robotics is shaping modern healthcare and manufacturing.

Medical Robotics Market Overview

The medical robotics market has grown rapidly due to advances in artificial intelligence, precision engineering, imaging integration, and data driven surgical planning. Medical robots are now used across multiple domains including robotic assisted surgery, rehabilitation, diagnostics, hospital automation, pharmacy automation, and medical device manufacturing.

Key growth drivers include aging populations, demand for minimally invasive procedures, surgeon ergonomics, consistency of outcomes, and integration of AI based decision support systems.

Top Medical Robotics Companies 2025

Several global companies are recognized as leaders in medical robotics

Intuitive Surgical

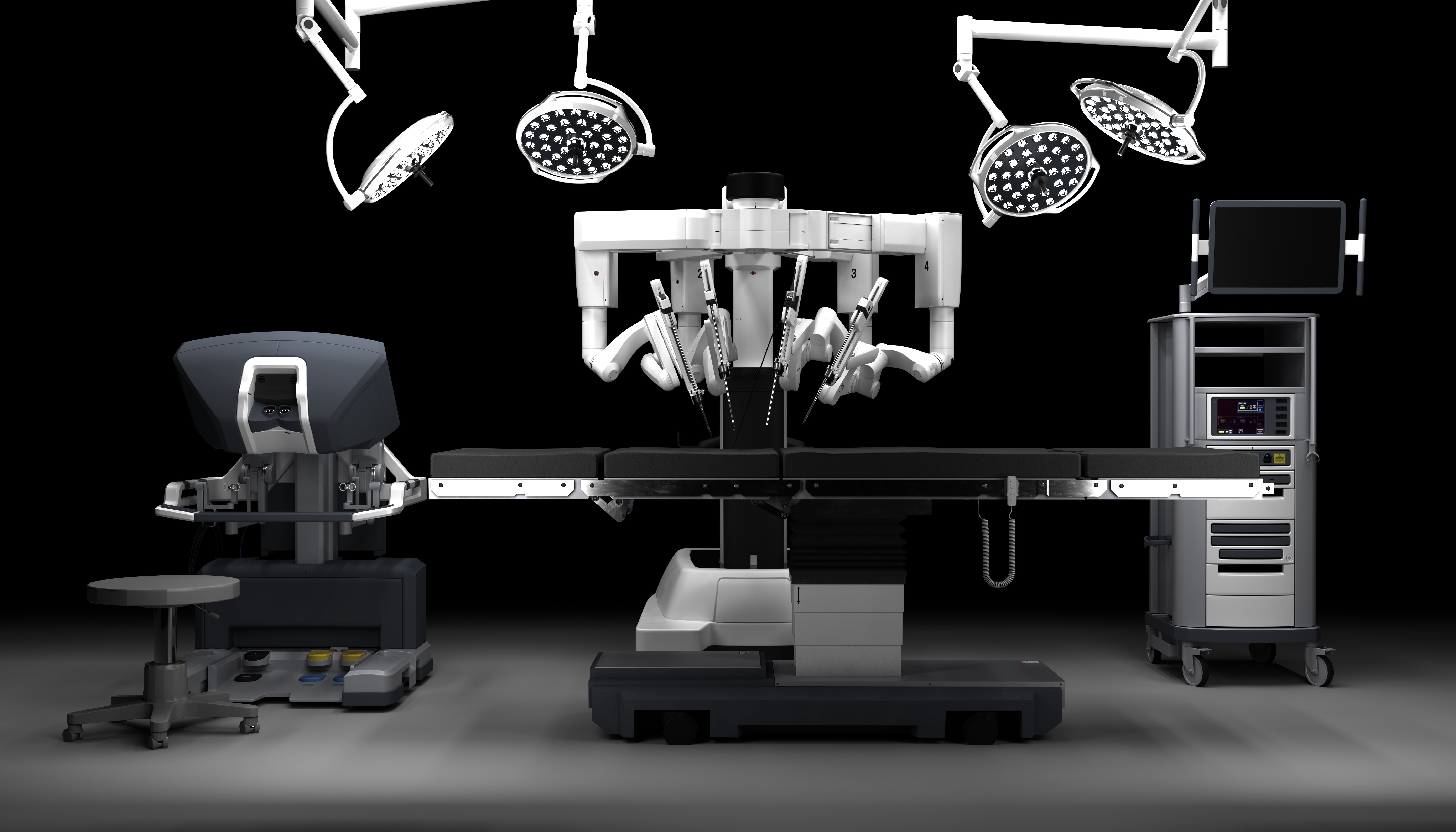

Known for the da Vinci robotic assisted surgery platform used in urology gynecology general surgery and cardiothoracic procedures

Medtronic

Developer of the Hugo robotic assisted surgery system and advanced surgical navigation technologies

Stryker

Producer of the Mako robotic arm system for orthopedic joint replacement

Zimmer Biomet

Creator of the ROSA robotic surgical assistant for brain spine and knee surgery

Johnson & Johnson

Developer of the Ottava robotic platform and digital surgery ecosystem

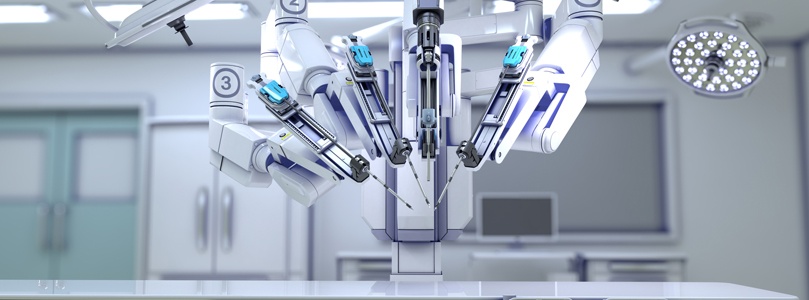

Business Segments of Intuitive Surgical Inc Related to Engineering Products

Intuitive Surgical operates across several interconnected business segments focused on engineering intensive medical products

Robotic Surgical Systems

This segment includes the da Vinci surgical platforms consisting of surgeon consoles patient side carts articulated robotic arms and high definition 3D vision systems

Instruments and Accessories

Single use and limited use robotic instruments such as graspers scissors needle drivers and energy devices designed for precision and sterility

Services and Support

System installation maintenance training programs digital upgrades and clinical support services for hospitals and surgical teams

Core Technologies

Key technologies include articulated arm mechanics motion scaling tremor filtration haptic feedback advanced optics real time imaging integration and software driven surgical workflows

Articulated Arm Machine Market

Articulated robotic arms are central to both medical and industrial robotics. In healthcare they enable precise multi axis movement in confined surgical fields. In manufacturing they support high accuracy assembly welding polishing and inspection tasks.

The articulated arm machine market continues to expand due to demand for micron level precision and repeatability.

Industrial and Automation Robot Manufacturers

These companies dominate manufacturing robots used in automotive electronics pharmaceuticals and medical device production

High Precision Robotics for Medical Parts Manufacturing

Medical device manufacturing requires extreme accuracy clean room compatibility and regulatory compliance. Robotics is used for

Microscale assembly of implants

Sterile packaging and inspection

Laser cutting and surface finishing

Quality control using AI vision systems

These solutions reduce human error and improve reproducibility of critical medical components

Robotics Markets with AI Ecommerce and Medical Integration

The most profitable robotics markets combining AI and digital commerce include

Robotic assisted surgery platforms

Pharmacy automation and medication dispensing

Hospital logistics robots

Medical device manufacturing automation

Rehabilitation and assistive robotics

AI enables predictive maintenance workflow optimization and outcome analytics across these sectors

Big Tech and Advanced Robotics Companies

Boston Dynamics

Known for advanced mobility balance and dynamic control systems primarily for research industrial and defense applications

Other global technology companies invest heavily in robotics through AI research cloud robotics and autonomous systems

Robotics Companies in India

India has a growing robotics ecosystem focused on industrial automation warehouse robotics and healthcare support systems. Many companies specialize in robotic arms AGVs surgical simulators and educational robots supporting domestic manufacturing and healthcare modernization

Types of Robots Used Across Industries

Industrial robots for manufacturing

Medical robots for surgery diagnostics and rehabilitation

Service robots for logistics and hospitality

Collaborative robots designed to work alongside humans

Autonomous mobile robots for warehouses and hospitals

Conclusion

Medical robotics and automation represent one of the most impactful intersections of engineering healthcare and artificial intelligence. From robotic assisted surgery systems to high precision manufacturing robots these technologies continue to improve safety efficiency and consistency across the healthcare ecosystem.

As a hospital institution this content is provided strictly for informational purposes. Clinical decisions and technology adoption should always be guided by regulatory approvals medical evidence and multidisciplinary evaluation.

If you want this turned into a structured SEO pillar page industry comparison table or medical robotics glossary, I can prepare that next.