The search for precision in making things has led to big steps forward in metal removal methods. As the global machining services market is set to grow a lot, how accurate these methods are is very important.

Precision engineering is key in today’s making things, with cnc machining and metal fabrication being vital for making top-notch parts. How well these methods work affects how well the final product does and how reliable it is.

Key Takeaways

- The importance of accuracy in metal removal techniques.

- An overview of different metal removal methods.

- The role of precision engineering in today’s making things.

- The effect of cnc machining on product quality.

- The importance of picking the right metal fabrication method.

The Science Behind Metal Removal

Understanding metal removal processes is key to their accuracy. It involves various techniques and technologies. These help precision-cut and shape materials.

Fundamental Principles and Mechanics

Metal removal is about the interaction between the cutting tool and the workpiece. This interaction is based on mechanics, including forces, velocities, and material properties.

Chip formation is vital in metal cutting. It affects the surface finish, tool wear, and process efficiency. Chip formation involves plastic deformation and fracture.

Evolution of Metal Removal Technologies

Metal removal technologies have changed a lot over time. Advances in materials science, mechanical engineering, and computer control systems have driven these changes. Today, we have traditional methods like turning and milling, and non-traditional methods like Electrical Discharge Machining (EDM) and laser cutting.

| Technology | Description | Advantages |

| Traditional Machining | Involves direct contact between tool and workpiece | High precision, versatile |

| Non-Traditional Machining | Uses energy-based processes (e.g., EDM, laser) | Capable of machining complex geometries, hard materials |

The need for higher precision, faster production, and working with various materials has driven these advancements. Knowing about these changes helps choose the right metal removal process for a task.

Precision and Accuracy in Manufacturing

Precision and accuracy are key in making products. They affect how well a product works and looks. In metalworking, getting these right is very important.

Defining Precision vs. Accuracy

Precision means how consistent measurements are. It shows how close results are when conditions are the same. Accuracy is about how close a measurement is to the real value. For example, a process might be precise but not accurate if it keeps making wrong parts.

Tolerance Requirements in Modern Industries

Today’s industries need very tight tolerance requirements. For example, aerospace parts must be within ±0.001 inches. This requires top-notch metalworking tools and advanced methods.

Economic Implications of Precision

Getting precise in manufacturing can be costly. But it also cuts down on waste and rework, saving money. Plus, precise products sell for more, making manufacturers more profitable.

In short, finding the right balance between precision, accuracy, and cost is vital. By focusing on these, makers can make better products, save money, and stay ahead in the market.

Conventional Metal Removal Methods

Traditional machining techniques are key in modern manufacturing. They offer various methods for removing metal. These methods have evolved to meet the growing need for precision and accuracy in different industries.

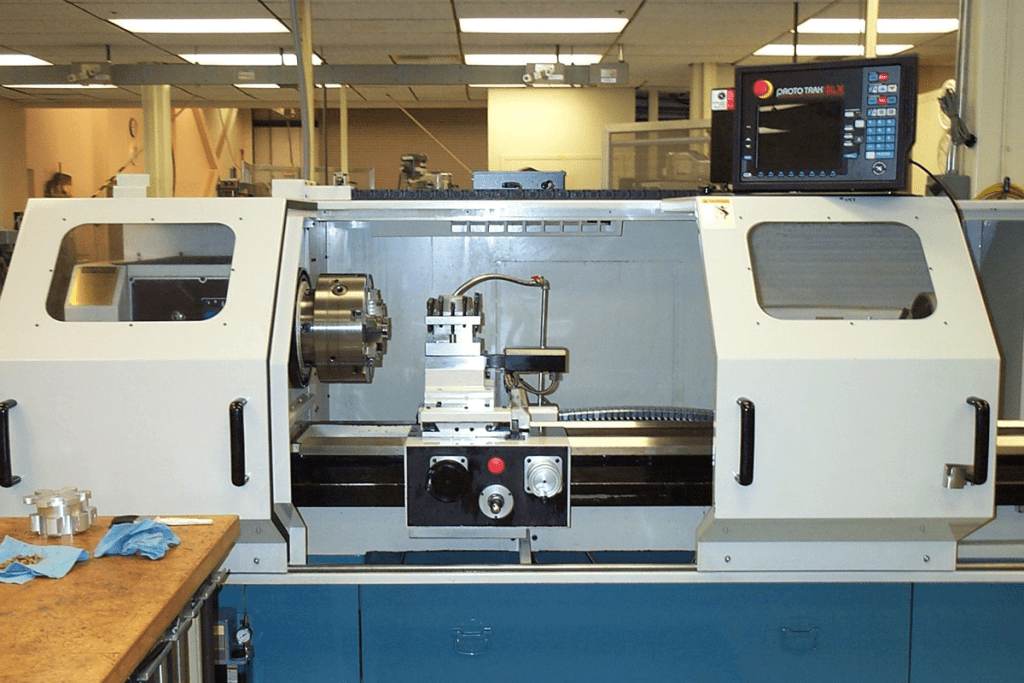

Turning Operations and Lathe Work

Turning operations remove material from a rotating workpiece. A lathe machine does this by rotating the workpiece while a cutting tool moves along the axis. Metal lathe operations can make many parts, from simple shapes to complex ones.

The precision of turning depends on the lathe’s rigidity, the cutting tool’s accuracy, and the workpiece’s stability. Modern lathes often have CNC controls to improve precision and consistency.

Milling Processes

Milling uses a rotating cutting tool to remove material from a stationary workpiece. Metal milling can create complex shapes and features. It’s very versatile and works with many materials and part shapes.

The accuracy of milling depends on the milling machine’s rigidity, the cutting tool’s precision, and how the workpiece is fixed. CNC milling machines offer high precision and can make detailed designs.

Drilling, Boring, and Reaming

Drilling, boring, and reaming are key for making and finishing holes in metal. Drilling makes new holes, boring enlarges existing ones, and reaming refines the hole’s diameter and finish.

| Process | Purpose | Typical Accuracy |

| Drilling | Create a new hole | ±0.1 mm |

| Boring | Enlarge an existing hole | ±0.01 mm |

| Reaming | Fine-tune hole diameter and finish | ±0.005 mm |

Conventional metal removal methods, like turning, milling, drilling, boring, and reaming, are vital in manufacturing. Knowing their capabilities and limits is essential for achieving the right precision and accuracy in metal parts.

Computer Numerical Control (CNC) Machining

Precision machining with CNC technology is key in today’s manufacturing. It uses computers to control tools, making metal removal accurate and efficient.

CNC Technology Fundamentals

CNC machining works by following programmed instructions. These come from Computer-Aided Design (CAD) software. They are then turned into G-code for the CNC machine.

First, a part is designed with CAD software. Then, the design is analyzed for the best machining strategy. This includes choosing tools and the order of operations.

Precision Capabilities of Modern CNC Systems

Modern CNC systems can achieve high precision. They can have tolerances as low as ±0.001 inches. This is thanks to better machine design, control systems, and tools.

CNC machining’s precision is also due to its ability to repeat operations. Once a program is set and tested, the CNC machine can make many parts with the same accuracy. This is great for making lots of parts.

Common Sources of Error in CNC Machining

Even with its precision, CNC machining can have errors. These include tool wear, machine deflection, and thermal distortion. Tool wear can cause parts to be off size over time. Machine deflection happens when cutting forces bend the machine or tool.

Thermal distortion is another big factor. Changes in temperature can make the machine and workpiece expand or contract. This can affect the machining’s accuracy.

Non-Traditional Metal Removal Processes

New machining techniques have opened up many possibilities in metal removal. These advanced methods solve complex problems better than old ways. They bring better precision and speed.

These new metal removal methods include EDM, laser cutting, and waterjet cutting. Each has its own uses and benefits.

Electrical Discharge Machining (EDM)

EDM removes metal without touching it, using electrical discharges. It’s great for making complex shapes and working with hard materials. Traditional tools can’t handle these tasks.

Key advantages of EDM include:

- Ability to machine complex shapes

- Works well with hard materials

- No tool contact with the workpiece

Laser Cutting and Ablation

Laser cutting uses a strong laser beam to cut materials precisely. It’s known for its accuracy and ability to cut complex shapes without tools.

Laser cutting offers several benefits:

- High precision and accuracy

- Versatile in material cutting

- Minimal heat-affected zone

Waterjet Cutting

Waterjet cutting uses a high-pressure water jet, sometimes with abrasive particles, to cut materials. It’s great for cutting thick or sensitive materials.

Advantages of waterjet cutting include:

- Can cut thick materials

- No heat-affected zone

- Environmentally friendly

Each non-traditional metal removal process has its own strengths and weaknesses. The right choice depends on the material, needed precision, and production needs.

Chemical and Electrochemical Metal Removal

Precision engineering needs special metal removal techniques like chemical milling and electrochemical machining (ECM). These methods are great for making complex parts with high accuracy.

Chemical Milling and Etching use chemicals to remove metal. Chemical milling removes material from a workpiece by using a chemical etchant. It’s perfect for making complex shapes and is used a lot in aerospace.

Chemical Milling and Etching

The chemical milling process starts with masking areas not to be etched. Then, the workpiece is dipped in a chemical bath that etches the metal. You can control how deep the etch is by changing the time and the etchant’s strength.

Chemical etching is used for making fine details and patterns on metal. It’s often used for making electronic parts and decorative items.

Electrochemical Machining (ECM)

Electrochemical Machining (ECM) is a special machining process. It uses an electrochemical reaction to remove metal. ECM is great for cutting hard or tough materials.

In ECM, the workpiece is the anode, and the tool is the cathode. An electric current is passed through the electrolyte. This dissolves metal from the anode, effectively machining it.

ECM has many benefits, like making complex shapes without stress or heat. It’s used in aerospace, automotive, and medical device making.

Both chemical milling and ECM are precise and can make parts with complex shapes. They are key tools in modern manufacturing. They help make parts that traditional methods can’t.

Critical Factors Affecting Metal Removal Accuracy

The accuracy of metal removal processes depends on several key factors. These factors must be optimized for high precision in manufacturing. Understanding their interplay is essential.

Material Properties and Machinability

Material properties greatly affect how easy it is to cut or shape metals. Machinability is the ease of cutting or shaping. Hardness, toughness, and thermal conductivity are important. For example, very hard materials can be hard to machine and need special tools.

“The machinability of a material is a key factor in metal removal accuracy,” experts say. Knowing material properties helps choose the right cutting tools and settings.

Cutting Tool Selection and Wear

Choosing the right cutting tools is critical for metal removal accuracy. Cutting tool wear affects machining precision. Wear happens due to friction, heat, and stress during machining. Keeping tools in good condition is important.

Tools with advanced materials and coatings, like carbide and diamond, last longer and work better. The right tool geometry and material are key for each task.

Machine Rigidity and Vibration Control

Machine rigidity and controlling vibration are essential for accuracy. Machine rigidity is the machine’s ability to resist cutting forces. Vibration can cause poor finishes and lower accuracy.

Today’s machines have features to reduce vibration, like damping systems. Proper setup and maintenance also help improve rigidity and reduce vibration.

Thermal Effects and Compensation

Thermal effects during machining can cause accuracy issues. Thermal compensation techniques help manage these effects.

Using coolants, thermal insulation, and monitoring temperature helps keep temperatures stable. Some CNC machines have algorithms to adjust for thermal changes.

In summary, achieving high accuracy in metal removal requires careful attention to material properties, tool selection, machine rigidity, and thermal effects. By managing these factors, manufacturers can enhance precision and efficiency in machining.

Measurement and Quality Control in Metal Removal

In metal removal, precision is key. It’s achieved through careful measurement and quality control. Making sure the final product meets standards is vital for its performance and life span.

Metrology Tools and Techniques

Metrology, the science of measurement, is vital in quality control. Tools like Coordinate Measuring Machines (CMMs), optical comparators, and laser scanning systems help measure complex shapes precisely.

Common metrology techniques include:

- Contact measurement using touch probes

- Non-contact measurement using optical or laser sensors

- Surface roughness measurement

International Standards and Tolerance Classifications

Standards like ISO 286 and ASME Y14.5 guide tolerance classifications. They ensure parts are made to specific standards. Knowing these standards is key for parts to fit together right.

| Tolerance Classification | Description | Typical Application |

| IT01-IT04 | High precision tolerances | Precision gauges, high-end machinery |

| IT05-IT12 | General manufacturing tolerances | Automotive, aerospace, general machinery |

In-Process vs. Post-Process Measurement

In-process measurement checks parts as they’re made. It lets makers adjust in real time. Post-process measurement happens after parts are made. Both methods have their uses, based on what the production needs.

In-process measurement is beneficial for:

- Reducing scrap by detecting errors early

- Improving process control

- Enhancing productivity

Choosing between in-process and post-process measurement depends on several factors. These include production volume, part complexity, and how critical the measurements are.

Industry-Specific Applications and Requirements

The precision metal removal industry serves many sectors, each with its own needs. These needs include accuracy, precision, and specific material properties. This drives the creation of tailored metal removal techniques.

Aerospace and Defense

The aerospace and defense sectors need high precision and reliability. Parts must handle extreme conditions like high temperatures and stresses. Advanced CNC machining and EDM are key for making complex aerospace parts.

- Tight tolerances and complex geometries

- Use of high-strength, lightweight materials

- Compliance with strict industry standards

Medical and Dental Implants

Medical and dental implants need precise making for biocompatibility and function. Laser cutting and micro-machining are used for detailed designs and smooth surfaces.

- Biocompatibility and material selection

- High surface finish requirements

- Complex geometries for implant functionality

Automotive Precision Components

The automotive sector depends on precision metal removal for durable and high-performance components. CNC machining and grinding are key for making engine and transmission parts.

- High-volume production with consistent quality

- Tight tolerances for optimal performance

- Material selection for durability and weight reduction

Electronics and Semiconductor Manufacturing

Electronics and semiconductor manufacturing need precise metal removal techniques. Chemical etching and laser ablation are used for making small components with high accuracy.

| Industry | Key Requirements | Common Techniques |

| Aerospace | High precision, complex geometries | CNC machining, EDM |

| Medical | Biocompatibility, high surface finish | Laser cutting, micro-machining |

| Automotive | High durability, tight tolerances | CNC machining, grinding |

| Electronics | High precision, miniaturization | Chemical etching, laser ablation |

Each industry faces unique challenges and needs, leading to the need for specialized metal removal techniques. Understanding these needs is key to developing effective manufacturing solutions.

Selecting the Right Metal Removal Process

Choosing the right metal removal process is key to making a product both high-quality and cost-effective. Manufacturers need to think about several factors to pick the best method for their needs.

Decision-Making Framework

A clear decision-making framework is vital for picking the right metal removal process. It should look at the material’s properties, the needed surface finish, how precise the parts must be, and how many will be made. By looking at these, manufacturers can find the best process.

- Material Properties: How easy the material is to machine, its hardness, and how it conducts heat all play a part in the choice.

- Surface Finish: The finish needed will tell you how precise and what type of process is required.

- Dimensional Tolerances: Parts that need to be very precise require advanced processes.

- Production Volume: The amount being made can decide between traditional and advanced methods.

Application-Based Selection Criteria

Each application has its own needs for metal removal processes. For example, aerospace parts need high precision and complex shapes, making CNC machining or EDM good choices. On the other hand, car parts might focus on being cost-effective and quick to make, leaning towards traditional machining.

When picking a metal removal process, consider the specific needs of each industry and application. This includes the material’s properties, how complex the parts are, and any rules that must be followed.

Economic Considerations

Economic factors are very important in choosing metal removal processes. The cost of the equipment, tools, labor, and energy used varies a lot between methods. Also, how much scrap is reduced and if extra steps are needed can affect the total cost.

| Process | Cost Factors | Economic Benefits |

| CNC Machining | High equipment cost, skilled labor | High precision, reduced scrap |

| EDM | Energy consumption, electrode wear | Complex geometries, hard materials |

| Conventional Machining | Lower equipment cost, simpler tooling | High production rates, cost-effective |

By looking at these economic factors, manufacturers can find a metal removal process that meets both cost and performance needs.

Emerging Technologies in Precision Metal Removal

New technologies are changing how we remove metal with precision and speed. These changes help meet the complex needs of today’s manufacturing.

Hybrid Manufacturing Processes

Hybrid manufacturing mixes different tech to get the best results. For example, adding 3D printing to traditional methods lets us make complex shapes with great detail.

Benefits of Hybrid Manufacturing:

- More flexibility in making things

- Higher precision from combining tech

- Less waste of materials

Artificial Intelligence and Adaptive Control

Artificial Intelligence (AI) and adaptive control are changing metal removal. They let us make adjustments and predict when things need fixing.

Key Applications of AI in Metal Removal:

- Forecasting tool wear

- Optimizing processes in real-time

- Automating quality checks

| Technology | Application | Benefit |

| AI-Powered Monitoring | Real-time process adjustment | Improved accuracy and reduced downtime |

| Adaptive Control Systems | Automatic parameter adjustment | Enhanced precision and efficiency |

Micro and Nano-Scale Metal Removal

New tech in micro and nano-scale metal removal is creating tiny parts with detailed designs.

This tech is key in fields like electronics and medicine. Here, making things at the micro and nano level is essential.

Examples of Micro and Nano-Scale Applications:

- Creating micro-electromechanical systems (MEMS)

- Making nano-scale surface features

- Designing detailed medical implants

Conclusion

The comparison of metal removal techniques shows how important precision engineering is today. Different methods, like CNC machining and non-traditional processes, have their own benefits. They help make accurate and precise results.

In industries like aerospace, automotive, and medical devices, precise parts are key. Knowing the strengths and weaknesses of each machining service helps manufacturers improve their work. This leads to better production processes.

Choosing the right metal removal process depends on several things. These include the material’s properties, how precise the parts need to be, and the cost. As manufacturing keeps growing, new advancements in precision engineering and material removal will be key.

Employing advanced metal removal techniques and CNC machining enhances product quality. It also cuts down on costs and makes companies more competitive worldwide.

FAQ

What should I wear for a PET scan?

Wear comfy, loose clothes without metal for a PET scan. You might need to change into a gown to avoid metal interference.

Do I need to remove jewelry and other metal items before a PET scan?

Yes, take off jewelry, glasses, and metal items for the scan. This includes belts, bras with metal, and clothes with metal parts.

How can I stay warm during a PET scan?

Bring a blanket or wear warm clothes for the scan. Just make sure they don’t have metal.

What is the difference between precision and accuracy in metal removal?

Precision means consistent measurements. Accuracy means how close those measurements are to the real value. Both are key in metal removal.

How do material properties affect metal removal accuracy?

Material hardness and machinability greatly affect accuracy. Knowing these properties helps choose the right tools and methods.

What are some common sources of error in CNC machining?

Errors in CNC machining come from tool wear, machine rigidity, and heat. Understanding these can help improve precision and accuracy.

What are the advantages of non-traditional metal removal processes like EDM and laser cutting?

Non-traditional methods like EDM and laser cutting are precise. They’re great for complex shapes and hard materials where traditional methods fail.

How do I select the right metal removal process for my application?

Choose based on material, desired precision, and cost. A framework can help make this decision.

What are some emerging technologies in precision metal removal?

New tech includes hybrid manufacturing, AI, and micro/nano-scale removal. These improve accuracy, efficiency, and work with complex materials.

References

- Blodgett, T. M., Becker, M., Bruesewitz, M., & Townsend, D. W. (2011). PET/CT Artifacts. Radiologic Clinics of North America, 49(1), 107-119.