Laser ablation is a high-intensity technique used in various industries, including medicine. Despite its benefits, it has several drawbacks that need to be considered. Learn how long can you walk after brain tumor surgery. Understand the importance of early mobilization clearly.

We explore the limitations and challenges associated with laser ablation, a procedure used in medical treatments. While it offers several advantages, understanding its disadvantages is key for both patients and medical professionals.

As we dive into the world of laser ablation, its disadvantages become clear. They can significantly affect treatment outcomes. In this article, we will look at the possible drawbacks of this technique.

Key Takeaways

- Laser ablation has several disadvantages that need to be considered.

- Understanding the limitations of laser ablation is critical for patients and medical professionals.

- The technique has several drawbacks that can impact treatment outcomes.

- Laser ablation requires careful consideration of its possible disadvantages.

- Medical professionals must weigh the benefits and drawbacks of laser ablation.

Understanding Laser Ablation Technology

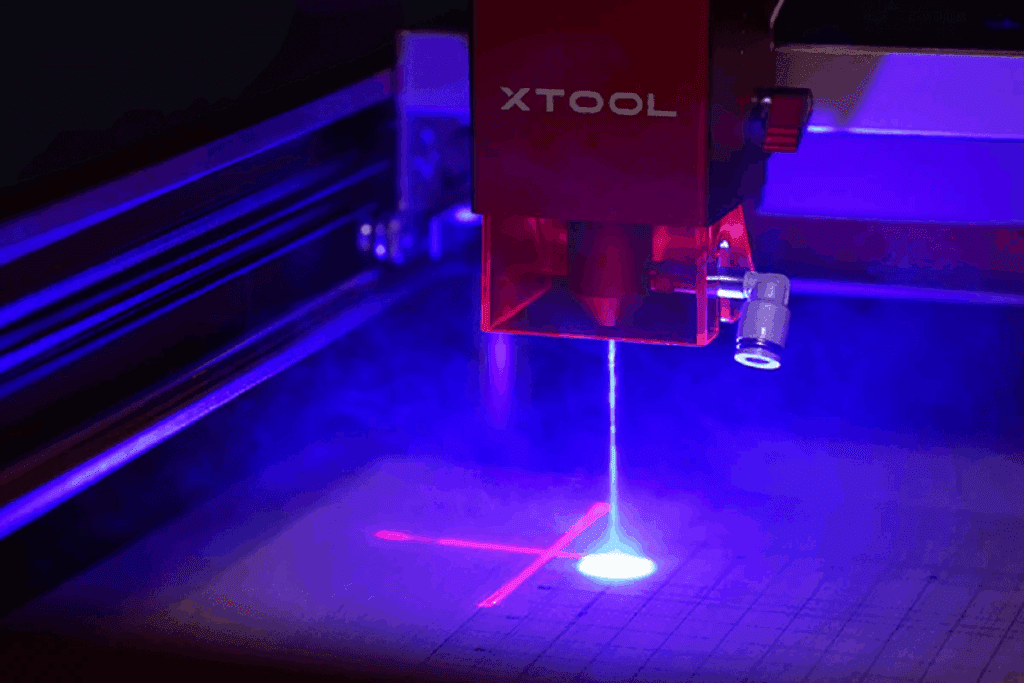

Laser ablation uses a focused laser beam to remove material from a surface. It’s crucial in various industries like medicine, manufacturing, and research. This is because it’s precise and versatile.

Definition and Basic Principles of Laser Ablation

Laser ablation works by using a high-intensity laser beam on a target material. This causes the material to vaporize or be removed. The efficiency of this process depends on the laser’s wavelength, pulse duration, and the material’s properties.

We’ll look into how these factors affect the ablation process. This will give us a full understanding of what laser ablation can do and its limits.

Common Applications in Industry and Research

Laser ablation is used in many ways across different fields. In industrial settings, it’s for material processing, surface modification, and precise machining. For example, it’s used in making semiconductors and other electronic parts.

In research environments, laser ablation helps with elemental analysis through LA-ICP-MS. It’s also used to study material properties and create new materials.

- Material processing and surface modification

- Precision machining and micromachining

- Elemental analysis through LA-ICP-MS

- Research and development of new materials

By understanding laser ablation’s principles and uses, we can see its full value and its boundaries in different areas.

The Working Mechanism of Laser Annealing and Laser Ablation Machine Which Uses High Intensity

High-intensity lasers are key in laser annealing and ablation. They offer precise control over power and focus. This makes them great for material processing.

High-Intensity Laser Systems Explained

High-intensity laser systems focus a lot of energy on a small area. This creates a powerful beam. The beam’s intensity, pulse duration, and focus can be adjusted for different tasks.

Key components of high-intensity laser systems include:

- High-powered laser sources

- Advanced beam delivery systems

- Precision control software

Together, these parts allow for the precise control needed for laser annealing and ablation.

Differences Between Laser Annealing and Ablation

Laser annealing and ablation both use high-intensity lasers but for different reasons. Laser annealing heats materials to change their structure. This improves their conductivity or strength.

Laser ablation, on the other hand, removes material by vaporizing it. It’s often used for surface preparation or to remove material.

| Process | Purpose | Effect on Material |

| Laser Annealing | Modify material properties | Alters microstructure |

| Laser Ablation | Remove material | Vaporizes surface material |

Knowing these differences helps choose the right technique for each task.

Technical Limitations of Laser Ablation

It’s key to know the technical limits of laser ablation for better use in many fields. Laser ablation is precise and flexible, but it faces some hurdles.

Precision and Accuracy Challenges

Keeping precision and accuracy in laser ablation is a big challenge. Things like laser beam quality, pulse duration, and material properties play big roles in how well it works.

- Laser beam quality impacts how focused and intense the ablation is.

- Pulse duration affects the thermal damage and detail of the ablation.

- Material properties, like reflectivity and thermal conductivity, change how well it works.

Material-Dependent Performance Issues

Laser ablation works differently with each material. For example, transparent materials are hard to ablate because they don’t absorb laser energy well. And highly reflective surfaces can cause damage to the laser system with back reflections.

- Transparent materials need special laser wavelengths or methods.

- Highly reflective surfaces need changes in laser power and how it’s delivered.

- Composite materials are tricky because of their mixed properties.

Knowing these issues helps us improve laser ablation for certain tasks. This makes it more efficient and precise.

Heat-Related Disadvantages

Laser ablation is precise but has big heat problems. It removes material with a laser beam, creating a lot of heat.

Looking at the heat issues with laser ablation, we see big concerns. Thermal damage changes the treated material’s properties.

Thermal Damage to Surrounding Areas

One big issue is thermal damage to surrounding areas. The laser beam heats more than just the target, causing changes or cracks.

This damage can weaken the material. It might make the component last less long. It’s key to control this heat to keep the material right.

Heat-Affected Zone (HAZ) Problems

The heat from laser ablation also creates a heat-affected zone (HAZ). This area has been heated too much, changing its properties.

The HAZ can have problems like changed microstructure, stresses, and less corrosion resistance. These issues can hurt the material’s performance. It’s important to reduce the HAZ size.

By tackling these heat problems, we can make laser ablation better. This way, it works well and has fewer downsides.

Surface Quality Issues After Laser Ablation

Surface quality issues are a big problem after laser ablation. This is because the process can leave surfaces rough and uneven. This is a big deal for things that need to be very precise.

We look at the surface quality issues after laser ablation. We focus on what causes these problems and how they affect things.

Roughness and Irregularities

Laser ablation can make surfaces rough and uneven. How bad it is depends on the material, the laser settings, and the technique used. For example, high-intensity lasers can make surfaces even rougher because they transfer more energy.

These uneven surfaces can be a big problem for the final product. For example, in medical device manufacturing, rough surfaces can hold bacteria. This could lead to infections.

Redeposition of Ablated Material

Another problem with laser ablation is when the removed material falls back onto the surface. This creates a layer of debris that needs to be cleaned up. The amount of debris depends on the environment and the laser’s pulse.

We need to think about these factors to improve laser ablation. By understanding why surfaces get rough and uneven, we can find ways to fix these issues. This will help make the treated surface better.

Limitations in Laser Ablation ICP-MS Applications

Laser ablation ICP-MS has many benefits but also faces some big challenges. It’s a key tool in fields like geology, environmental science, and materials science. Yet, it’s not perfect.

Analytical Challenges and Inaccuracies

One big issue with laser ablation ICP-MS is the analytical challenges it brings. These can cause results to be off, which is a big problem in some cases. For example, the sample’s makeup can greatly affect how accurate the results are.

Some major analytical challenges include:

- Matrix Effects: The sample’s makeup can impact the analysis results.

- Fractionation Effects: Elements might not be ablated stoichiometrically, leading to wrong sample composition.

- Instrumental Drift: Over time, the instrument’s performance can change, affecting precision.

Sample Preparation Difficulties

Sample preparation is another area where laser ablation ICP-MS struggles. The quality of sample prep directly affects analysis accuracy. Some issues include:

- Ensuring the sample is evenly mixed and truly represents the material.

- Preparing samples with complex shapes or those hard to handle.

- Managing samples that easily get damaged by the laser ablation process.

Good sample prep requires careful thought to avoid errors.

Calibration and Standardization Problems

Calibration and standardization are key for accurate element quantification with laser ablation ICP-MS. But, there are several hurdles. For instance:

- Lack of Matrix-Matched Standards: No standards that match the sample matrix can cause big errors.

- Difficulty in Preparing Standards: Making standards that match the samples is hard.

- Instrument Variability: Different instrument performance can mess up calibration and standardization.

Overcoming these issues needs careful planning and execution for reliable results.

In summary, laser ablation ICP-MS is a powerful tool but has its limits. Understanding and tackling these challenges is key to getting the best results.

Industrial Laser Ablation Drawbacks

Laser ablation in industry faces several big challenges. These issues affect its efficiency and how widely it’s used.

Production Speed Limitations

One major problem is how slow laser ablation can be. It’s very precise but not as fast as old methods. This is a big issue for industries that need to make lots of things quickly.

Companies are working to make laser ablation faster without losing quality. They’re improving lasers and how materials are moved around.

Integration Challenges with Existing Manufacturing Processes

Adding laser ablation to old production lines is hard. Many lines are set up for traditional methods. Changing to laser ablation means big changes to equipment, training, and how things are done.

We need to make sure laser ablation works well with current production setups. This might mean updating old machines or changing how things are made.

Scalability Issues for Mass Production

Scalability is a big problem for laser ablation in industry. Growing production while keeping quality up is hard.

Companies are putting money into research to make laser ablation better for big production. They’re working on stronger lasers and better controls to keep quality high even when making more things.

Economic Disadvantages of Laser Ablation Systems

Using laser ablation technology comes with big economic costs. We need to look at the economic downsides of these systems. Several factors add up to their cost.

High Initial Investment Costs

The biggest cost is the high price to buy and set up laser ablation systems. This can be too much for small to medium-sized businesses. The cost of top-notch laser gear, safety features, and training is high.

Initial costs include:

- Purchase price of the laser ablation equipment

- Installation and setup expenses

- Training for personnel to operate the equipment safely and effectively

Maintenance and Operational Expenses

After buying, laser ablation systems need regular upkeep and running costs. These costs can make using the technology hard to justify. Maintenance includes servicing, replacing parts, and upgrading to keep the system working well.

Operational expenses to consider:

- Energy consumption costs

- Consumables and replacement parts

- Maintenance personnel costs or service contracts

Return on Investment Challenges

Getting a good return on investment (ROI) is tough for laser ablation users. The high start-up costs and ongoing expenses mean the system must work well to make money or save costs. But, things like downtime, maintenance, and needing skilled workers can make ROI hard to figure out.

Strategies to improve ROI:

- Optimizing production schedules to minimize downtime

- Investing in operator training to maximize efficiency

- Regular maintenance to prevent costly repairs and extend equipment lifespan

In summary, laser ablation systems have great benefits but also big economic downsides. These include high start-up costs, upkeep and running costs, and challenges in getting a good ROI. Knowing these points helps businesses decide if laser ablation is right for them.

Energy Consumption Concerns

Laser ablation’s energy use is a big deal for both cost and performance. It’s important to understand and tackle these energy issues to make laser ablation better.

Power Requirements for High-Intensity Lasers

High-intensity lasers need a lot of power to work well. The power needed changes based on the material and the task. For example, harder materials need more power to ablate.

The power needed for these lasers is often in kilowatts. This can make the cost of using them high. It’s not just about the power, but also how well the laser turns electrical energy into light.

Energy Efficiency Challenges

Boosting laser ablation’s energy efficiency is tough. The efficiency of a laser depends on how well it turns electrical energy into laser light. Many lasers lose a lot of energy as heat.

To solve these problems, scientists and makers are looking at new laser tech. For example, fiber lasers are more efficient and use less energy than older types.

- Fiber lasers are better because they’re more efficient and need less upkeep.

- They also have better beam quality, which helps with precise laser ablation.

Cooling System Demands

The high energy use in laser ablation means a lot of heat. Keeping this heat under control is key to the laser’s stability and life. Cooling systems help get rid of this heat.

These cooling systems can be complex and use a lot of energy. Designing them well is vital for laser ablation’s reliable use.

New cooling tech is helping with these issues. Better heat exchangers and cooling fluids can make cooling systems more efficient.

In summary, laser ablation faces big energy challenges. These include high power needs, energy efficiency issues, and big cooling demands. Solving these problems is key to making laser ablation more affordable and green.

Laser Ablation Services: Challenges for Service Providers

Laser ablation service providers face big challenges. They must ensure quality, manage client expectations, and repeat processes well. These issues affect how well they do their job.

Difficulties in Maintaining Quality Control

Keeping quality high is a big challenge. Laser ablation is complex and needs careful setup. Changes in materials, lasers, and environments can affect quality. It’s hard to keep quality the same for all clients.

Experts say, “High precision in laser ablation needs advanced tech and knowledge of materials and applications.” This knowledge helps solve quality problems.

Managing Client Expectations

Managing what clients expect is another big challenge. Clients have specific needs for laser ablation. Good communication and understanding client needs are key.

- Understanding client requirements and constraints

- Providing clear and realistic expectations regarding the outcomes of laser ablation

- Maintaining open lines of communication throughout the project

Ensuring Process Repeatability

Repeating the process is vital. Clients need consistent results. Good process control and detailed records help ensure this.

“Repeatability is not just about achieving the same results; it’s about understanding the variables that can affect the process and controlling them effectively.”

— Expert in Laser Ablation Technology

By tackling these challenges, providers can do better. They can make clients happier and stay ahead in the market.

Medical Applications: Limitations and Risks

Laser ablation in medicine has both benefits and drawbacks. It’s important to know the challenges it poses. This technology is used in many medical fields, but it’s not without risks.

Tissue Damage Concerns

One big worry is tissue damage. The strong laser can harm nearby tissues. This can lead to serious complications.

Healing and Recovery Complications

Healing after laser ablation can be tough. The problems faced vary by application and patient health.

Precision Challenges in Clinical Settings

Getting precise is key in medical laser use. But, it’s hard to keep precision in a clinical setting. This can affect how well treatments work.

To grasp the risks, let’s look at some data:

| Application | Risks | Mitigation Strategies |

| Dermatological Treatments | Tissue damage, scarring | Precise calibration, post-procedure care |

| Neurosurgical Procedures | Damage to surrounding neural tissue | Advanced imaging techniques, real-time monitoring |

| Cardiovascular Treatments | Thrombosis, vessel perforation | Intravascular imaging, careful patient selection |

Each medical use of laser ablation has its own risks. Knowing these and using the right strategies can help improve results for patients.

Safety Hazards and Precautions

Laser ablation can be dangerous, with risks like radiation exposure and airborne contaminants. It’s important to know how to stay safe.

Laser Radiation Risks

Laser ablation can harm your eyes and skin. Wearing the right eye protection and covering your skin is key.

The danger level depends on the laser’s power and type. Class 4 lasers, often used in ablation, are very risky. They can cause eye damage through reflections.

Airborne Contaminants from Ablated Materials

The process of laser ablation can release harmful particles into the air. Good ventilation and wearing PPE are vital to avoid inhaling these particles.

The type of material being ablated affects the kind of contaminants released. For example, some metals can produce toxic fumes.

| Hazard | Precaution | Equipment |

| Laser Radiation | Eye Protection, Skin Covering | Laser Safety Glasses, Protective Clothing |

| Airborne Contaminants | Ventilation, PPE | Fume Extractors, Masks |

Required Safety Protocols and Equipment

Following safety rules is essential for safe use. This includes keeping the laser in good condition, training staff, and using the right safety gear.

Regular safety checks and following safety standards are also critical. This means following rules from groups like OSHA and ANSI.

Knowing the dangers of laser ablation and taking the right precautions helps keep everyone safe at work.

Environmental Concerns

Laser ablation technology is growing, but we must think about its impact on the environment. This method removes material from surfaces using lasers. It’s used in many industries, but it also has big environmental worries.

Waste Generation and Disposal

Laser ablation creates waste, which is a big problem. The materials removed can be harmful if not thrown away right. We need good ways to manage this waste to protect our planet.

Getting rid of this waste safely is key. We must collect, store, and dispose of it carefully. Places using laser ablation must follow strict environmental rules to avoid harming the environment.

Ecological Impact of Ablation Byproducts

The leftovers from laser ablation can hurt our environment. They can include harmful particles, gases, and substances. We must stop these from getting into the air and water.

- Particles can make the air dirty and harm people’s health.

- Toxic gases can mix with other air pollutants, making things worse.

- Byproducts can also pollute our water if not handled right.

Regulatory Compliance Challenges

Places using laser ablation face tough rules to follow. These rules change a lot, making it hard for companies to keep up. Keeping up with these changes and following the rules is key to protecting our planet.

Companies can use sustainable practices and new tech to cut down waste and emissions. Regular checks and studies help find ways to do better.

Limitations in Specific Materials Processing

Laser ablation is precise but faces big challenges with certain materials. Its success depends a lot on the material’s properties.

Challenges with Transparent Materials

Transparent materials are hard for laser ablation to handle. The laser beam goes through them easily, making it tough to get the desired effect. This can lead to inefficient processing and damage to nearby material.

Materials like glass and some polymers are very tricky. They don’t absorb the laser well, so more intense lasers are needed. This makes the process harder and increases the risk of damage.

Difficulties with Highly Reflective Surfaces

Highly reflective surfaces also complicate laser ablation. Metals that reflect a lot of the laser beam reduce the energy for ablation. This makes the process less efficient and can harm the laser system.

To solve these problems, special techniques and tools are used. For example, shorter laser pulses or changing the angle of incidence. But these steps can make the process more complex and expensive.

Composite Material Processing Issues

Composite materials, made of different substances, add extra challenges. The varied properties of these materials can cause uneven ablation. This makes it hard to get a smooth surface.

In composites with a polymer and metal, the different thermal and optical properties can cause uneven ablation. This can lead to damage like delamination.

| Material Type | Challenge | Potential Solution |

| Transparent Materials | Lack of absorption | Higher laser intensity, specialized coatings |

| Highly Reflective Surfaces | Backreflection, reduced absorption | Angle adjustment, shorter pulse durations |

| Composite Materials | Uneven ablation rates | Optimized laser parameters, multi-step processing |

In conclusion, laser ablation is a powerful tool but has its limits with specific materials. By understanding these challenges and finding solutions, we can improve its use for more applications.

Comparison with Alternative Technologies

When looking at laser ablation, it’s important to compare it with other technologies. These include chemical etching, mechanical processing, and plasma processing. Each has its own benefits and drawbacks for material processing.

Chemical Etching vs. Laser Ablation

Chemical etching is a common method for removing material, often for detailed patterns. It uses chemicals to dissolve material, unlike laser ablation’s high-intensity beam. Chemical etching is great for complex shapes without heat damage, which is good for some materials.

But, chemical etching has downsides. It uses dangerous chemicals, which can harm the environment and health. It also takes longer than laser ablation for some materials.

Mechanical Processing vs. Laser Ablation

Mechanical methods like milling and drilling are traditional for removing material. They are precise but struggle with hard or brittle materials. These materials can be hard to machine without damage.

Laser ablation is better for these materials. It works without touching the material, reducing damage risk. This is great for delicate or complex shapes.

Plasma Processing vs. Laser Ablation

Plasma processing uses ionized gases to remove material or change surface properties. It’s effective for certain tasks, like surface modification.

It can be better than laser ablation for some materials or surface changes.

But, plasma processing might not be as precise as laser ablation for detailed work.

In summary, laser ablation has many benefits. But, other technologies like chemical etching, mechanical processing, and plasma processing are better for specific tasks. The choice depends on the application and material.

Conclusion

We’ve looked into the downsides of laser ablation, a tech used in many fields. It faces challenges like precision and accuracy issues. Also, how it works can vary with different materials, affecting its performance. There are also economic hurdles, like the high costs of starting up and running laser systems. Safety is another big concern, with risks from laser beams and harmful particles in the air. This means we need strict safety rules. Environmental worries, like waste and harm to nature, are also important. Knowing these issues helps us tackle the problems of laser ablation. This way, we can use it better and reduce its negative effects. In short, laser ablation has its good points, but we must think about its bad sides too. This helps us use it wisely and avoid its downsides.

FAQ

What is laser ablation, and how does it work?

Laser ablation uses a strong laser beam to remove material from a surface. The laser energy turns the material into vapor or ejects it, creating a precise cut.

What are the common applications of laser ablation?

It’s used in many fields like material processing, medical treatments, and analytical techniques like ICP-MS. It’s known for its precision and versatility with different materials.

What are the main technical limitations of laser ablation?

It faces challenges in precision, accuracy, and how it works with different materials. Each material reacts differently to the laser, affecting the results.

How does laser ablation affect the surrounding material?

It can damage the area around it with heat and create zones affected by heat. This can change the material’s properties.

What surface quality issues can occur after laser ablation?

Issues include roughness, unevenness, and material redeposition. These problems can lower the quality of the final product and may need extra work.

What are the challenges of using laser ablation in ICP-MS applications?

Challenges include possible inaccuracies in analysis, hard sample preparation, and calibration issues. These can affect the analysis’s reliability.

What are the industrial drawbacks of laser ablation?

Drawbacks include slow production, integration issues with current processes, and scalability problems for large-scale use. These affect its use in big projects.

What are the economic disadvantages of laser ablation systems?

Disadvantages include high upfront costs, ongoing maintenance, and operational expenses. It’s a big financial investment.

How does laser ablation impact energy consumption?

It needs a lot of power for the lasers, which is energy-intensive. It also requires cooling systems, adding to energy use.

What challenges do service providers face in laser ablation?

Providers face issues in quality control, managing client expectations, and ensuring consistent results. These are key for reliable service.

What limitations and risks are there in medical applications of laser ablation?

Risks include tissue damage, healing complications, and precision challenges in medical settings. These need careful consideration.

What safety hazards are associated with laser ablation?

Hazards include laser radiation risks, airborne contaminants, and the need for safety protocols and equipment. These are essential to prevent harm.

What environmental concerns are associated with laser ablation?

Concerns include waste generation, the ecological impact of byproducts, and regulatory compliance. These need careful management to protect the environment.

How does laser ablation perform with different materials?

Its performance varies with material type. It faces challenges with transparent materials, reflective surfaces, and composites.

How does laser ablation compare to alternative technologies?

It’s compared to technologies like chemical etching, mechanical processing, and plasma processing. Each has its own advantages and disadvantages, depending on the application and material.

References

National Center for Biotechnology Information. Evidence-Based Medical Insight. Retrieved from https://www.ncbi.nlm.nih.gov/pmc/articles/PMC6164857/